Studentsof Final Year Textile S.V.I.T.S. Indore

ABSTRACT

Water and soil repellency has been one of the major targetsfor fiber and textile scientists and manufacturers for centuries. Combinationsof new materials for fiber production with a variety of surface treatments havebeen developed to reach the condition of limited wettability.

Nature has already developed an elegant approach that combineschemistry and physics to create super repellant surfaces as well as selfcleaning surfaces. Lotus leaves is the best example of self cleaningsurfaces. The concept of self cleaning textiles is based on the lotus plantwhose leaves are well-known for their ability to self-clean by repellingwater and dirt. More recently, botany and nanotechnology have united to explorenot only the beauty and cleanliness of the leaf, but also its lack ofcontamination and bacteria, despite its dwelling in dirty ponds.

Basically, the lotus leaf has two levels of structureaffecting this behavior micro-scale bumps and nano-scale hair-like structures coupled with the leafs waxy chemical composition. On the basis of lotus leafconcept scientist developed a new concept Self cleaning textile thetextile surface which can be cleaned itself without using any launderingaction.

Nano technology provides a new concept self cleaningtextiles which gives self cleaning as well as fresh cloths every day, this notonly technically benefited but techno economically also benefited.

INTRODUCTION

Nanotechnology has real commercial potential for the textileindustry. This is mainly due to the fact that conventional methods used toimpart different properties to Fabrics often do not lead to permanent effects,and will lose their functions after Laundering or wearing. Nanotechnology canprovide high durability for fabrics, because nano-particles have a largesurface area-to-volume ratio and high surface energy, thus presenting betteraffinity for fabrics and leading to an increase in durability of the function.In addition, a coating of nano-particles on fabrics will not affect theirbreath ability or hand feel. Therefore, the interest in using nanotechnologiesin the textile industry is increasing.

There are basically two types of self-cleaning surfacesinvolving nanotechnology. In the first place extremely water repellent,microscopically rough surfaces: dirt particles can hardly get a hold on themand are, therefore, removed by rain or by a simple rinse in water .The secondexample is given by photo-catalytic layers: due to a layer of nanocrystallinetitanium oxide, fouling organic material is destroyed by solar irradiation.

Self cleaning surface having a water contact angle greaterthan 150degree and a very low roll off angle. Water through these surfaceseasily rolls off and completely cleans the surface in the process. Selfcleaning fabrics not only resist coffee and red wine stains but are alsorepellant to water, dirt, odour and are antibacterial as well.

MANUFACTURING METHOD:

The self cleaning textiles can be manufactured byapplication of either fluorocarbons or by nanotechnology.

HOW FLUOROCARBONS WORK?

Principle-If the critical surface tension of solid is more than the surface tension of liquid, then liquid will wet the solid. So if the critical surface tension of solid is reduced than that of liquid, the water repellency can be achieved. And the effect can be imparted on fabric by using fluorocarbons, which are the carbon compounds containing perfluorinated carbon chain. They form thin film around the fibre and as they possess a very low surface tension of around 10dyne/cm, the drop does not adhere to the surface fibres.

LIMITATION:

- Good durability cannot be obtained for cotton.

- Fluorine compounds may cause skin related problems.

- Effect will reduce after few washes.

To overcome these problems new methods have been developed using nanotechnology.

The manufacturing of self-cleaning textiles using nanotechnology:-

- Using Photo catalyst

- Using microwaves

- Using carbon nanotubes

- Using Metal oxide colloidal

- Using silver nanoparticles

- Using chlorine halamine

1. Using Photo catalyst

Starting with photocatalysts. It is catalytic self-cleaning process. In this process Nano-sized , titanium dioxide and zinc oxide are used for imparting self cleaning and anti-bacterial properties .The fabric is coated with a thin layer of titanium dioxide particles heaving 20 nanometers diameter. Titanium dioxide is a photocatalyst; when it is illuminated by light of energy higher than its band gap, electrons in TiO2 will jump from the valence band to the conduction band, and the electron (e) and electric hole (h+) pairs will form on the surface of the photocatalyst. The negative electrons and oxygen will combine to form O2 . radical ions, whereas the positive electric holes and water will generate hydroxyl radicals OH.. Since both products are unstable chemical entities, when the organic compound i.e. dirt, pollutants, and micro organisms falls on the surface of the photocatalyst it will combine with O2 - and OH- and turn into carbon dioxide (CO2) and water (H2O).Since the titanium dioxide acts as a catalyst, so it is never used up. This is how the coating continues breaking down stains over and over. Zinc oxide is also a photocatalyst, and the photocatalysis mechanism is similar to that of titanium dioxide.

PHOTOCATALYTIC SELF CLEANING

The self-cleaning fabrics work using the photocatalytic properties of titanium dioxide, compound used in many new nanotechnology solar cell applications. The fabric is coated with a thin layer of titanium dioxide particles that measure only 20 nanometers in diameter. When this semi-conductive layer is exposed to light, photons with energy equal to or greater than the band gap of the titanium dioxide excite electrons up to the conduction band. The excited electrons within the crystal structure react with oxygen atoms in the air, creating free-radical oxygen. These oxygen atoms are powerful oxidizing agents, which can break down most carbon-based compounds through oxidation-reduction reactions. In these reactions, the organic compounds (i.e. dirt, pollutants, and micro organisms) are broken down into substances such as carbon dioxide and water. Since the titanium dioxide only acts as a catalyst to the reactions, it is never used up. This allows the coating to continue breaking down stains over and over.

Working of self cleaning textiles

2. Using microwaves

New technology attaches nanoparticles to clothing fibers using microwaves. Then, chemicals that can repel water, oil and bacteria are directly bound to the nanoparticles.These two elements combine to create a protective coating on the fibers of the material. This coating both kills bacteria, and forces liquids to bead and run off. The same technology, created by scientists working for the U.S. Air Force, has already been used to create t-shirts and underwear that can be worn hygienically for weeks without washing.

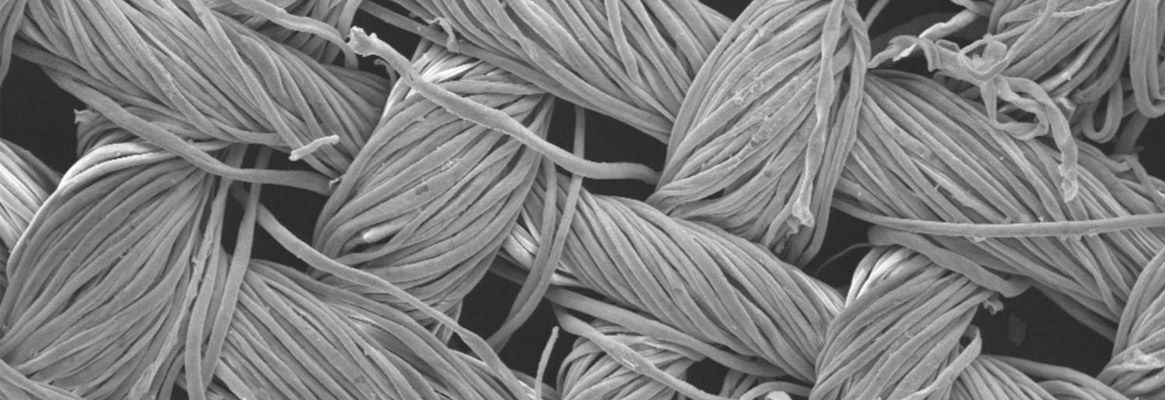

3. Using carbon nanotubes

Artificial lotus leaf structures were fabricated on textiles via the controlled assembly of carbon nanotubes. Carbon nanotubes (CNTs) and surface modified carbon nanotubes (PBA-g-CNTs) are used as building blocks to biomimic the surface microstructures of lotus leaves at the nanoscale. Cotton fabrics, which otherwise have perfect water absorbabilities, have been endowed with super-hydrophobic propertieswater contact angles greater than 150 were measured. The method provides a bionic route to create hydrophobic textiles. Furthermore, considering the novel mechanical and electric properties of carbon nanotubes, these carbon nanotubes coated cotton fabrics will find potential application in sensing, conducting and special textiles.

TREATED COTTON FABRIC

4. Using Metal oxide colloidal:

The fabric is dipped and processed in metal oxide colloidal solution and then is through heat treatment so as to make the fabrics with surface roughness on nanometer scale. Then through water repellent treatment, the fabrics has surface with water contact angle above 150.degree.

5. Using Silver nanoparticles:

A highly water-repellant coating made of silver nanoparticles that can be used to produce suits and other clothing items that offer superior resistance to dirt as well as water and require much less cleaning than conventional fabrics. Nano-Tex improves the water-repellent property of fabrics by creating nanowhiskers, which are made of hydrocarbons and have about 1/1000 of the size of a typical cotton fiber. They are added to the fabric to create a peach fuzz effect without lowering the strength of cotton.

(a)Untreated textile surface (b)Treated textile surface

The diagram shows that the two textile surface one which is treated with silver nano particles and other is not treated with silver nano particles.

The untreated surface having dust particles, when water droplets rolls over it do not get washed off because dust particles are adhere by textile surface. While treated textile surface do not adheres the dust particles hence when water particles rolls over it dust get washed off.

In fig. (b) Silver nano particles treated surface shows self cleaning property

6. Using chlorine halamine

The technology works by attaching chlorine-containing molecules called halamines to textile fibers. Chlorine in the form of halamines has powerful bacteria-killing properties, used for example to disinfect swimming pools. Unlike chlorine gas, there are no adverse effects since toxic chlorinated carbon atoms are not generated. By sticking halamines to the cellulose fibers in cotton, the bacteria-killing effect can be bonded to the material and used again and again. Eventually, the chlorine is used up but can be regenerated with a wash in chlorine bleach. The halamine-treated fabrics kill microorganisms almost instantly on contact, so these materials are best suited for medical uses such as uniforms, wipes, bedding and towels.

Photo catalytic degradation of odors compound:

A photo catalytic acrylic fiber SELFCLEAR yarn with higher-dimensional self-cleaning properties which had been exclusive with conventional photo catalytic fibers, and started recently sailing their product for manufacture of clothing, sportswear, uniforms, bedding, carpets, and daily goods. Because titanium oxide is applied into SELFCLEAR yarn, it has a higher self-cleaning activity with deodorant, antibiotic, and anti-soiling properties as well as excellent functional stability, as compared to fabrics using a conventional photo catalytic reaction. SELFCLEAR yarn has a multi-layer structure with micro voids tens of nanometers in diameter on the surface of the acrylic fiber, and that makes it a nanovoid structure creating a greater surface area .Because special nano-sized photo catalytic titanium oxide, one-tenth the size of conventional titanium oxide used for fibers, is used for SELFCLEAR yarn, it has a ten times greater surface With this synergistic function of double nano-technology, it can produce excellent effects on higher selfcleaning functions with deodorant, antibiotic and anti-soiling properties compared to fibers using conventional photocatalytic reactions

Photo catalytic degradation of

odorous component

AREAS OF APPLICATION:

- Hospital garments

- Sports wears

- Military uniform

- Upholstery

LIMITATIONS OF SELF CLEANING FABRIC:

Breakthroughs in nanotechnology have made self-cleaning fabrics both practical and economical. With commercial production making the technology readily available to the masses, will washing machines and laundry detergent become obsolete?

There are several factors limiting how quickly current self cleaning fabric would be able to break down organic compounds. Sunlight is the best source of light for activating the self-cleaning process. A ketchup-stained shirt would have to be left outside in the sun for at least a day in order to remove the stain. However, for military persons or hikers, who are outside in the sun for long periods of time without the time or means to clean their clothes, self-cleaning fabric would be ideal. It's also important to note that the newly developed method for producing self-cleaning fabric has only been developed for cotton.

Further research would be required

to test ways of applying titanium dioxide nanofilms to other textiles.

PROBLEMS WITH SELF-CLEANING FABRIC:

The main reasons that self-cleaning fabrics require a lot of time to break down stains is because titanium dioxide is very inefficient at using energy from sunlight. The titanium dioxide serves as a catalyst for the break down of dirt molecules by providing electrons that oxidize oxygen molecules in the surrounding air. The electrons are freed from the titanium dioxide via the photoelectric effect. But because of titanium dioxide's high band gap energy, only high energy blue and UV light photons have enough energy to excite electrons to the conduction band. High energy blue and UV light only make up 3% of the solar spectrum, so titanium dioxide can only use a very small portion of the sun's energy to break down stains.

Excitation of electrons to the conduction band is only the beginning of the

cleaning process. These electrons must then react with oxygen atoms, which then

react with the dirt particles. All of these reactions are limited by access to

and the amount of freed electrons in the titanium dioxide. So for a large

stain, a lot of light energy is needed before the fabric can fully break it

down.

CONCLUSION:

The realization of self-cleaning properties on textile surfaces by using the nanotechnology includes a vast potential for the development of new materials or new products and applications for known materials. The opening of new application fields for textiles will lead to a new growth stage. For the growing market of technical textiles a further increase in production volume, sales and application fields can be expected by successful transfer of the self cleaning effect on textile materials. Structure based soil and water-repellent properties lead to an efficient use of materials and are therefore in agreement with the principles of sustainable development. The economic significance of the self cleaning textiles can be outlined as follows:

- Ease of maintenance and environmental protection because of reduced cleaning efforts

- Time, material, energy reduction and consequently cost-efficiency during production

- Makes textiles longer-lasting

- People need not to suffer from heavy laundry bills.

- Improved ageing behavior by extended surface purity effect.

ACKNOWLEDGEMENT:

First of all we would like to express profound gratitude to the management of the institute, Administrative officer Shri. R.C.Parmar, Principal Dr.Ing.V.P.Singh, Advisor Prof. Dr. H.V.S. Murthy and Head of the department Prof. Dr.Prabhakar Bhat for giving encouragement and guidance to work on SELF CLEANING TEXTILES AN OVERVIEW.

REFRENCES:

- A new

dimension to textiles/garments - Pradeep Kaira,

http://www.snaimpex.com/a_new_dimension_to_textiles.htm.

- Lotus-Effect

- A trade name under copyright for the patented self-cleaning super-hydrophobic

micro- to nano-structured surfaces

http://www.nees.un-bonn.de/lotus/en/faq_html.html.

- '

Self-cleaning' suits may be in your future, Mark T. Sampson,

http://www.voyle.net/Nano%20Textiles/Textiles-2004-006.htm.

- Selected

Applications of Nanotechnology in Textiles, Y. W. H. Wong, et al.

AUTEX Research Journal, Vol. 6, No 1, March 2006.

- Development

of New Textile Processing Technology Based on Nano-Technology-Nano-Scale

Coating Made Possible on Monofilament surface,

http://www.toray.com/news/fiber/nr041022.html.

- Japan Exlan develops photocatalytic acrylic fiber yarn

SELFCLEAR with titanium oxide,

http://textileinfo.com/en/plan/selfclear/.

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow

this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp