1.Introduction

Electronic may soon be integrated into textiles in our nearenvironment. These will benefit many traditional textile applications. It mayfind niches in many traditional textile applications. They are being developedfor communication, entertainment, health & safety. The technologist may oneday integrate multiple electronic devices directly into textile & apparelproducts using shared resources increasing the mobility, comfort &convenience of such device. The present paper was aimed at investigating thedevelopment in Electronic Textile Products.

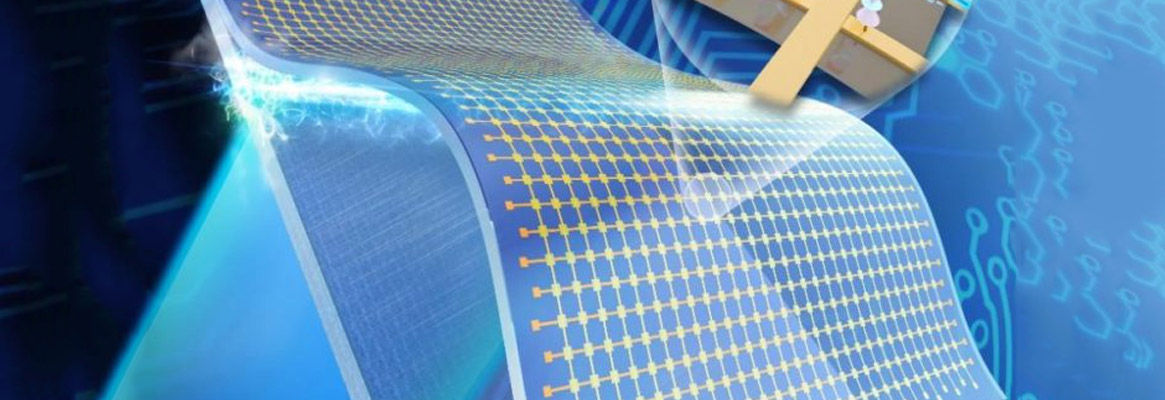

2. Electronic Textiles

Electronic Textiles are fabrics that have electronics andinterconnections wovens into them. Components and interconnections woven intothem. Components and interconnections are a part of the fabric and thus aremuch less visible and, more importantly, not susceptible to becoming tangledtogether or snagged by the surroundingd.Consequently, e-textiles can be worn ineveryday situations where currently available wearable computers would hinderthe user.E-textiles also have greater flexibility in adapting to changes in thecomputational and sensing requirments of an applications.

3. Implementation & Development of Electronic Textile

3.1 Construction Kit for Electronic Textiles

There are lots of reasons to avail construction kit to theusers. This kit may provide a means to attract more women & girls to thesetraditionally male dominated fields. In addition to this, this field is muchmore exciting which is being growing day by day. It may also inspire &educate the researchers to further grow up in this field. We also hope thatthis kit will surely be a useful prototyping tool for todays researchers.

Application of the Kit

To understand & explore the range of construction thatcan be built with the kit, some playful wearable e-textiles may be taken as anexample. This section will describe our creations- a set of communicatingshirts, a temperature sensitive hat etc.

Communicating Shirts

To experiment with the kits IR transceivers, we built twoshirts that communicate with one another wirelessly via IR. These shirts can beseen in Figure . The first shirt has a decorative bundle of flower like shapeson its front. One of these houses an RGB LED, one a vibrating motor encased ina pink wooden bead and one an IR transceiver. The second shirt has its hardwareas shown in the figure. This contains an IR transceiver, a touch switch adthree LED sequins.

Fig. also shows how the kit was employed to build the pieces.

These components are connected to one another via stitching in conductive

thread. We used a combination of hand and machine stitching to attach the

components to the garments.

The function of all the shirts is quite same as same IR signal is being constantly listened by shirt. When the first hears a signal, it replies to the message, turns on the vibrating motor to alert its wearer, and changes the color of the RGB LED to indicate the message it received. The second shirt sends out an IR signal whenever its switch is pressed. When the shirt receives a signal, it displays some information about the signal via its three LEDs.

3.2 Textronics

High quality can be established after integrating the microelectronics with textile & clothing constructions. The main task of textronics is to produce multifunctional, intelligent products with complex inner structures, but which have uniform functional properties, Textronic products are characterized by the following features:

- Flexibility - means facility in modifying the construction at the stage of design, production and exploitation; for example, modular constructions

- Intelligence of the textiles - referring to the possibility of an automatic change in the properties influenced by external factors (parameters).

- Mutifunctionality - the ease of realizing

3.3 Conductive Technologies

The area of IETs has emerged from the wearable computing

arena. At today, many of the wearable computing devices developed to date are

cumbersome and awkward, typically strapped or carried on the body. But,

textile-based wearable electronics that allow interactive touch, voice, and

body heat activation are being developed. The current versions use integrated

wiring and carrying devices that add bulk and weight to the garments making

them uncomfortable and impractical for daily use. These items are also

expensive and present issues relating to maintaince, flexibility & user

safety.

3.4 Component Integration

In spite of conductive materials used to develop an e-textile, the electronic components must be integrated in to textile to create an IET. The methods which can be used to accomplish electronic component can be soldering, bonding, stapling & joining. Soldering involves mounting the components directly onto the surface of a textile. This method achieves good electrical contact but it can cause adverse effect after getting in contact with skin. Bonding involves using conductive adhesives to embed components into textile substrates. Non-toxic, highly conductive, highly durable, and moderately flexible conductive adhesiveness can potentially be used to bond rigid components with flexible textile substrates.

Components can also be stapled into conductive stitched circuits to create electronic textile circuitry. When the substrate flexes or bends the conductive trace is free to move. However, such flexing stretches the pins that attach the component to the substrate, accelerating wear and tear on the textile. Joining involves attaching an electronic components thread frame directly to a stitched fabric circuit. Threads leading out of the electronic component can be stitched, punched, or woven through the substrate constraining the components to specific locations and allowing the conductive threads to be evenly balanced.

Conclusion

Though product development is still faced with many challenges, the future for IETs looks promising. Research and development efforts will enable product developers to overcome current challenges to advancing IET development.

References:

- Home page, http://www.technical-textiles.net, accessed April 2006.

- Home page, http://www.futurepundit.com , accessed May 2006

- http://enlighted.com/

- http://www.mp3blue.de/

- http://www.lumalive.com/

- http://www3.interscience.wiley.com/journal/121655064/abstract?CRETRY=1&SRETRY=0

- http://www.nature.com/nmat/journal/v6/n5/abs/nmat1884.html

- http://www.sciencemag.org/cgi/content/abstract/324/5924/232

About the Authors

Mr. Mohit Saluja has studied B.Tech in Textile Chemistry and is associated with The Technological Institute of Textile & Sciences, Bhiwani, Haryana and Ms. Richa Kukreja is pursuing her M.Tech from UIET (University Institute of Engineering and Technology), Kurushetra University, Haryana