Conductive fibres and yarns have drawn considerableattention during the last decade. Generally speaking, textile materials made oforganic polymers are perfect insulators. Due to weak electrical conductivityelectrical load is accumulated on the surface of organic polymers. Therefore,to prevent the accumulation of electrical load, to enhance the possibility ofelectrical load transfer and to obtain electromagnetic shielding effect, thetextile materials are turned into electrically conductor by using differentmethods.

Methods of producing conductive yarns can be summarized asfollows:

- Adding carbon or metals in different forms such as wires, fibres or particles (eg. core spun, blends)

- Using inherently conductive polymers

- Coating with conductive substances

Adding carbon or metals in different forms such as wires,fibres or particles:

It is possible to obtain textiles with conductive propertyby inserting carbon or metals such as silver, steel, nickel to the structure,in the form of wires, fibres, and micro or nano particles. Carbon fibres andcarbon filled fibres exhibit good conductive properties, but on the other hand,they have some aesthetic problems.

Metal fibres can be produced by using bundle-drawing processor shaving process. Metal fibres and wires which can be incorporated intotextile structures have high conductivity, but they have also somedisadvantages like their weight, cost and the damage which they can give to thetextile machinery.

Using Inherently Conductive Polymers:

Inherently conductive polymers are polyanyline, polyvinylalcohol, polypyrrole and polyamide 11 etc. Conductive polymers are still adeveloping area. Amongst these polymers polyanyline has attracted a lot ofattention due to its good environmental, thermal and chemical stability.Although it was discovered over 150 years ago, only recently has polyanilinecaptured the attention of the scientific community due to the discovery of itshigh electrical conductivity. Actually conductive polymers are gaining more andmore importance due to their advantages, but these polymers are still rathercostly. They can be used in applications where flexibility, low weight andconductivity are required.

Coating with Conductive Substances:

Another important aspect is using coated conductive fibres.Coating can be applied through various techniques. Conductive polyester yarnsand filaments of this kind are used in many application areas. Highlyconductive fibres can be produced by metallic or galvanic coating, but thesemethods have some limitations with adhesion and corrosion resistance andsuitability of the substrate. Metallic salt coatings have some limitations inconductivity.

By utilizing the conductive yarns in the fabric structures,various functionalities may be attributed to the fabrics. Enhancing both theproperties of textile structures and the function of conductivity, conductivetextiles have important applications not only in medical and military fields,but also in the fields of fashion, architecture and design for their aestheticappeal. Therefore textiles with conductivity function are used in manytechnical applications such as protection of people and electronic devices fromelectromagnetic interference (EMI) and electrostatic discharge, heating,wearable electronics, data storage and transmission, sensors and actuators.

Major Application Areas Of Conductive Textiles Can Be Grouped As Follows:

- Smart clothing

- Transport of electrical signals

- Heating

- Protection from electromagnetic interference and electrostatic discharge

Electromagnetic Waves and their Effects

Due to the increasing electromagnetic pollution caused by many factors such as TV and radio channels, mobile phones, studies about protection from electromagnetic waves have gained considerable importance.

Equipments such as mobile phones, radars, radios and some others radiate electromagnetic waves which may be harmful for both human health and sensitive electronic devices. In general, electromagnetic shielding may be defined as the process of restricting the effect of electromagnetic field between two areas.

Electromagnetic waves are formed by the combination of both electrical and magnetic waves and characterized by a frequency and a weave length. Electromagnetic interference (EMI) is known to effect sensitive electronic devices as well as the human health in a negative way. When a high frequency electromagnetic wave enters a human body, it vibrates molecules to give out heat. The network of veins within high risk organs such as the eyes could be weakened because this heat can not be easily dissipated. Moreover, it could increase the possibility of leukemia and other cancers.

Human nervous system can be considered as a huge electronic system with around 25 billion cells. The effect of electromagnetic fields onto the natural circulation of that system may be negative. Some problems in nervous system and blood circulation might occur due to this negative effect.

The electromagnetic shielding effectiveness of materials is essential especially in the applications where the protection of sensitive electronic devices and human health is taken into the consideration.

Figure below illustrates the possible electromagnetic radiation sources surrounding human beings in daily life.

Use Of Conductive Textiles In Electromagnetic Shielding:

Electromagnetic shielding effectiveness (EMSE) is defined as the degree of shielding against electromagnetic interference at a specific frequency. Electromagnetic energy is absorbed, reflected or transmitted by the materials.

An important factor for all electromagnetic shielding textiles is including the suitable amount of conductive yarns or other conductive components since conductive materials weaken the electromagnetic weaves by reflection.

Therefore, materials which are intended to be utilized in electromagnetic shielding applications must have the property of being electrically conductive. Smoother surfaces are preferred for better shielding effectiveness.

It is known that best materials used for electromagnetic shielding are based on metals. Metals are known to reduce the effects of radio waves, electromagnetic and electrostatic fields. The effectiveness of these materials depends on the type of the material used, connections of the conductive net and the frequency of the electromagnetic weave. However, since the materials based on metals have some disadvantages such as rigidity, heavy weight and weak comfort properties in end use, they are increasingly being replaced by thermoplastics especially for commercial applications due to high flexibility, light weight, low cost and etc.

Research On Electromagnetic Shielding Textiles At Ege University Textile Engineering Department:

Some studies and research on electromagnetic shielding with conductive textiles have started in the laboratories of Ege University Textile Engineering Department. The research is planned to cover the electromagnetic shielding (EMSE) properties of conductive yarns and fabrics, production of conductive yarns, their integration into the fabric structures with different designs, measurement and evaluation of the fabrics developed.

Production of EMS Textiles:

In the current research, trials will be made by producing woven and knitted textile structures, including conductive yarns either produced in the spinning laboratory of the department or supplied from the market. Afterwards, EMSE of these materials will be measured and the effect of yarn and fabric parameters (material type, yarn count, twist, and type of production, weight, construction, amount and distribution of conductive yarns in the fabric) on the shielding function will be investigated systematically.

EMSE Measurements:

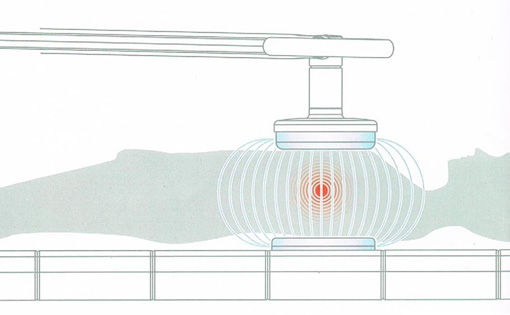

For EMSE measurements, the Electromagnetic Competence (EMC) Test Device will be used. The device consists of a shielded room and a Rhode& Schwarz testing equipment which includes an RF power amplifier, a signal generator, a spectrum analyzer and two antennas; one is connected to the signal generator and the other to the spectrum analyzer as receiver.

According to the basic principle of EMSE test, the sample is placed between a signal generator and a receiver, thus the amount of transmitted signals are measured and electromagnetic field blocked by the sample is calculated. The signal, generated in the signal generator is sent onto the sample through an antenna after being amplified. The amounts of signals transmitted by the sample are then detected by the receiver antenna, situated on the other side of the sample.

Schematic Demonstration of EMC Test System:

a) The sample opening on the shielded room and the receiver antenna inside the room

b) Placement of the copper coated textile sample in the sample opening,

c) Copper coated textile sample placed in the sample opening on the wall of the shielded room and the antenna

The measurements are carried out in standard laboratory conditions, in 10 kHz -1 GHz frequency range, since most of the electromagnetic radiation resources surrounding the humans in daily life, such as radio waves, GSM, etc. radiate in that frequency range. Therefore in general a shielding effectiveness of 40-60 dBV is aimed in our tests.

In a initial work the EMSE measurements was performed due to the standard EN50147-1, in 5 different frequencies; 200MHz, 400 MHz, 600 MHz, 800 MHz and 1 GHz. In the measurements, the shielding effectiveness of the sample is defined by finding the difference between the ideal signal value and the detected value of the signal.