Introduction

Composites are heterogeneous in nature, created by the assembly of two or more components with fillers or reinforcing fibres and a compactable matrix. The matrix may be metallic, ceramic or polymeric in origin. It gives the composites their shape, surface appearance, environmental tolerance and overall durability, while the fibrous reinforcement carries most of the structural load thus giving macroscopic stiffness and strength. A composite material can provide superior and unique mechanical and physical properties because it combines the most desirable properties of its constituents while suppressing their least desirable properties.

Fibreglass reinforced plastic (FRP), commonly known as fibreglass, is a thermoset plastic resin that is reinforced with glass fibres. A plastic resin comes in two different classes: thermosets and thermoplastics. The plastic resin system determines chemical, electrical, and thermal properties. Fibre provides strength, dimensional stability, and heat resistance. Additive provide colour and determine surface finish, and affect many other properties like weathering and flame retardancy. Processing of FRP composites involves complex chemical action. Final properties are determined by many factors, including the type, amount and composition of the resin systems and reinforcements. In addition, the use of an additive can greatly affect the FRP composite properties.

Glass fibre

Glass fibres are among the most versatile industrial materials known today. They are available in virtually unlimited supply.3 All glass derived from compositions contain silica. They exhibit useful bulk properties like hardness, transparency, resistance to chemical attack, stability and inertness as well as desirable fibre properties like strength, flexibility and stiffness.4 Glass fibres are used in the manufacture of structural composites, printed circuit boards and a wide range of special purpose product. (5)

Reusing and recycling of glass fibres

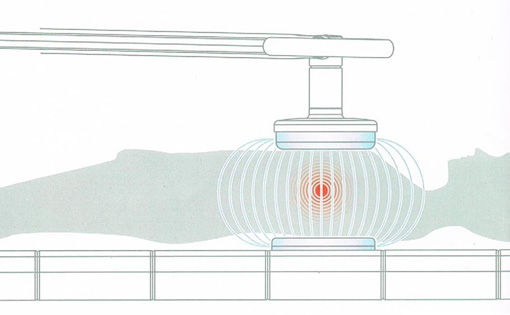

The use of FRP composites as high-performance material is increasing in aerospace, military, automobile and sports industries. It is very difficult to separate the fibre, filler polymer and resin if we are using glass fibre from a landfill without recycling, which is very dangerous. So recycling of the FRP composite is essential. Although researchers have developed new technologies to recycle FRP, fibres obtained from these technologies are short and fluffy, and are not treated after recycling. Longer fibres are more valuable, and for producing these, a new technology, called the steam system, was developed. Initially superheated steam system was used, but the fibres produced had lower tensile strength.

High-value recycled reinforced fibre with high performance can be re-manufactured into FRP. For that the surface modification of the fibre is necessary after recycling. Resin, which is over the surface of the fibre, is removed. Treated glass fibre and recycled carbon fibres can be re-manufactured by vacuum-assisted resin transfer molding (VARTM).

References

1. www.asminternational.org 2001 ASM International. .ASM Handbook, Vol. 21: Composites (#06781G)

2. Loewenstein K.L, The Manufacturing Technology of Continuous Glass Fibers, 3rd revised. Elsevier, 1993

3. Wallenberge F.T r, Structural Silicate and Silica Glass Fibres, in Advanced Inorganic Fibres Processes, Structures, Properties, Applications, F.T. Wallenberger, Ed., Kluwer Academic Publishers, 1999, p 129-168

4. Wallenberger F.T., Melt Viscosity and Modulus of Bulk Glasses and Fibres: Challenges for the Next Decade, in Present State and Future Prospects of Glass Science and Technology, Proc. of the Norbert Kreidl Sym- posium (Triesenberg, Liechtenstein), 1994, p 63-78

5. Dr. Scott W. Beckwith SAMPE Journal, SAMPE International Technical Director and President, BTG Composites Inc., Taylorsville, UT Volume 45, No. 5, September/October 2009

6. Dr. Scott W. Beckwith SAMPE Journal, SAMPE International Technical Director and President, BTG Composites Inc., Taylorsville, UT Volume 45, No. 5, September/October 2009

7. Hex Force Reinforcements www.hexcel.com