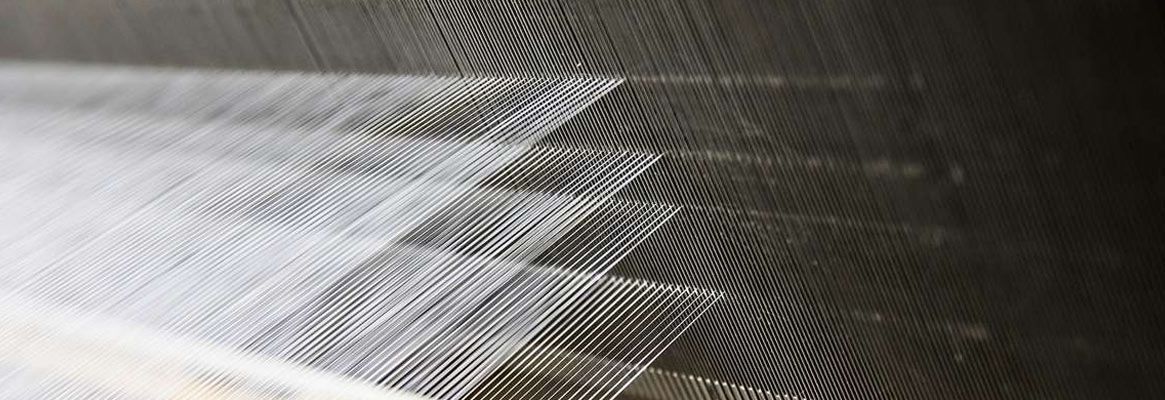

The time of thinking fibers as source of producing clothingand home textile products is still vibrant in the market, however, the wave ofinnovation is inundating higher. Land, water and air- all are witnessing thefascinating services of textiles. Today, it is one of the gigantic disciplinesof product development for engineering applications. In terms of the materialperformance, textiles can be seen working at the interdisciplinary level byoffering the several technical advantages that may not be accumulated in asingle material traditionally known.

The companies and countries not cultivating any naturalfiber crop; or least significant in such activity are in a position of makingmilestone achievement through innovative development, and producing engineeredtextiles. Being resourceful in bringing up innovation with an enhanced researchand technology incubation cycle the industrialized countries, including USA, Western Europe, and Japan made better advancement, however, the Asian achievers China and India are becoming significant.

What has turned the textile materials to be in demandingposition for out of home articles! It is the functional character in producing the desired performance. There are several factors supporting the increased consumptionof textiles in special applications. Over the past several decades, textilefibers have captured an inevitable position in composition and as an integralpart of product structure.

The advancement in material science has placed an increasedemphasis in finding novel or innovative substitutes to excel in performance theexisting composites. Lighter in weight, flexible in handling, soft in touch,comparable in strength with metals, modifiable in size and shape; and all thesecharacteristics in an affordable price had provided the interesting novelapplications to textile materials. Therefore, it is not unusual to realize astream of innovative fibrous composition in above and beneath the land space.

Illuminating the advanced value in textiles has an influenceon traditional growing country to appreciate the spirit of innovation, placemind set beyond yarn and grey cloth, and attempt to generate an enhancedcontribution to techno- socio development of country.

Today, the textile fibers are significantly serving theplaces including air craft, aerospace, health care, automotives, geoconstruction, transportation and physical protection. There are several textilearticles or constituting units from the construction and design of cabin tohighly specialized clothing products including g- suits for pilots, and entrysuits for space shuttle where significant contribution of textile fibers isevident.

Variation in environmental conditions; and gravitationalforce in aerospace operations posed specific requirements for safety andfunctional performance. Therefore, the textile clothing being next to skin haspivotal standing.

It is not unusual to see the interest of NASA, USA, through the research and development activities in the production and testing of textilearticles for Mars Exploration Mission. Aerospace textile is an area oftechnical textiles that covers special finished products to engineeredtextiles. It includes the textile containing articles for specific functionalrequirements to work in aircrafts, space shuttles, lunar and mars mission, andspace transportation.

The world market of technical textile products was estimatedto 16.7 million tones in 2000 with the value of US $ 92.88 billions. This was projected for the year of 2010 to 23.77 million tones worth of US $ 127 billions (1). The stateof the art technology in Europe and USA coupled with the availability of highlytrained and educated work force provide definite advantage in the developmentof technical textiles and the ease of capturing the market. In these regions textile products falling under the category of technical textiles approach to 40 % of the total textile manufacturing.

There are several countries working in the domain of conventional textiles with the generous land and environmental resources of producing natural fibers particularly cotton. The little awareness and interest in the area of technical textiles is evidently reflected in major cotton growing developing countries, however, the case of India is significantly different. The motivation created decades back now emerging in significant research projects, public allocations and private investment.

The interest in the development of technical textile has significantly grown in India reflected in the 11th five year plan (April 2007- March 2012). There were several important schemes, projects and capital investment to promote the technical textile sector. The National Mission for Technical Textiles was launched in September 2007. This Mission has to use an allocation of US $ 170 million in five year period to develop the technical textile industry to a size of around US $ 12- 15 billion (2).

Impressive growth results in Indian technical textile industry are predicted in the next two decades in comparison to the last three decades of USA and Europe. More recently, an allocation of Rs. 440 millions was sanctioned by the Indian Government for establishing four centers of excellence to encourage the technical textile industry (3).

In Pakistan, interest development yet demands continual appreciation of the subject, and the progression in the interdisciplinary approaches prior the materialized achievement. Little developing interest may be seen in studies. It was in 2005, when a study project on g-suit was executed at the textile department of NED University, Karachi, in association with the concerned public aviation department (4). Such interesting studies are supportive to realized subject importance and are presently demanded using justified competency.

G-suit is an interesting and significantly useful textile product in aerospace operation. It is a type of garment generally in the form of tightly fitting trousers (5). It is worn by aviators to control the blood circulation at higher level of acceleration. The g-suit is designed to reduce blood flow to lower side of human body under the influence of acceleration or deceleration (6); therefore the desired functions of pilots are achievable.

Generally, a g-suit is composed of inflatable bladders, containing air or liquid that can be pressurized using a g-sensitive valve and held firm to legs and abdomen under higher values of g. It may also be termed as anti- gravity suit for being utilized to deal with the accelerated motion against the gravity.

The principle desired function of g- suit is to resist the blood draining from brain and upper body parts to legs of aviators. This effect results in preventing the loss of conscious and the variation in the level of visibility of aircraft pilot.

The initial effect of blood pooling in lower parts is a reduced level of vision termed as grey- out (= browning of scene). Stronger vision loss is termed as tunnel- vision, and the ultimate result is a black- out effect called g-induced loss of consciousness (g- LOC) (5).

The effects of g-LOC were known since 1917 (6). However, in World War II, higher performance planes were used and this problem became significant. In the following next decades to post World War II, the next generation of aircrafts had experienced significantly increased level of acceleration. It was doubled from 4.5g to 9g.

Currently the g- suits are available that can retain the aviator consciousness under an acceleration of 9g. An indication in g- suit innovation and development may be seen in Popular Science Magazine, California (USA). The magazine had recognized an Air Force Test Pilot School tested prototype anti- gravity suit in the top-100 technology development of 2000 (7).

The physical effects experienced by the fighter pilot, as a result of rapid changes in the acceleration, influence the movement of his body. Typically, in few seconds a pilot weighing 160 pound can feel a nine times gain in his weight reaching to 1440 pounds.

Suiting for astronauts is another interesting area of textiles contribution in space operations. The influenced of surrounding experienced by the astronauts is verily different from the one dealt by the pilots. The clothing used in space crafts is generally called space suits. The missions involved in the study of space exploration had used the engineered textile clothing. For example, NASA (National Aeronautic and Space Administration) had been an important user of space suit pressure garment. Apollo A7LB was the first highly mobile space suit that helped astronauts to walk on the lunar surface in late 1960s (8).

Apollo, Skylab, Space Shuttle, International Space Station (ISS) and Constellation had befitted from the performance of textile materials. However, all these were of highly specialized nature in design, material development, fabrication, testing and quality assurance relative to the conventional textiles.

In space shuttle the requirements for the mobility of astronauts are inevitable, and these significantly depend upon the design and nature of spacesuit. Extra- Vehicular Activity (EVA) is influenced by the space-suit performance. Space Shuttle Extravehicular Mobility Unit (EMU) can be described as a waist entry suit with a hard upper torso (HUT) and relatively softer mobility joints made of fabric (9). EMU suits were particularly to work in zero gravity.

For planetary exploration, improved mobility and waist flexing are important for moving down and up for kneeling and ground features study. Entry method is considered as a desired feature, and the space suits had been named in terms of entry types. These include waist entry, rear entry, bi-planar entry and soft zipper type entry. Several characteristics of space- suit including suit sizing, suit mass, suit volume, suit comfort etc., are resulted from the entry type.

The considerations of vehicle and surrounding interfaces including air locks, hatches and manned rover (a small vehicle launched from a Lander and used to explore the surface of the moon or planet) are addressed in the design of entry type. Mission requirements and functional performance of astronauts are different for zero gravity operation, where EMU is used, relative to the planetary activity.

There had been significant interest in the continual improvement of I-Suit for achieving desired performance. There was Desert Research and Technology Study (RATS) led by advanced Extravehicular Activity (EVA) team from NASA Johnson Space Center with the participation of ILC Dover (10).

The Desert RATS testing confirmed the easy character of donning (to put-on) and doffing (to take-off) of rear entry I-Suit.

The aerospace suits are the special textile clothing articles to work in space. Textile fabric with specific character can be used in producing devices that assist the movement and transportation of objects in aerospace.

Parachute is a type of space textiles contributing in the space operations. It is effectively contributing in aerospace motion for men and materials. Parachutes help the safe decent of person or material from aerospace to ground surface. These can also be used for horizontal deceleration of fixed- wing aircraft.

The introduction of parachute is more of innovative discovery in nature, rather than a tool developed for war time games. To date, it has significant contribution in peaceful and life supporting aero- transportation of goods.

Interestingly the early developing activity for parachutes had used a dog as passenger in demonstration. The textile part used was made of linen stretched over wooden frame. Later on silk was used for being lighter and stronger. The evidence for the development of parachute can be traced in 9th century; however, the roots of modern parachute may be in the 18th century (1783) in France (11).

Generally, a parachute composes of thin light- weight fabric, supporting tapes and suspension lines. Nylon, polyester, Kevlar and Nomex fiber types can be used in producing fabric for parachute. The tethers connecting the parachute to back shell are made of Kevlar.

Significant physical properties are demonstrated by the fibers including Kevlar, Nomex types fibers. An example is the strength of Kevlar fibers which is five times greater than steel on an equal weight basis. The toughness and high rigidity are useful to produce engineered textiles where resistance to cut and shock is desired.

Flexibility and weathering resistance of fibers provide interesting features to achieve in aerospace operations. The forces acting upon the parachute following its full expansion are addressed in developing the design of parachute. Typically, these forces can be calculated from the atmospheric density, velocity, parachute drag area and mass (12).

Anti- gravity suits, space suits and parachutes are the few examples effectively serving the aerospace operations. However, there are several others and more could be innovated. Some other examples include the textile articles used as the constituent part of aircrafts, and are known to significantly add in the style, design and construction (13). Traditionally, such components include curtains, upholstery fabrics, wall cover, headrest, sheepskins etc. The items can be tailored for the design and comfort, and for added protection requirements these can be rendered flame retardant.

Today, the textile fibers are significantly recognized for the performance required in specialized applications. The field of technical textiles has gained significant interest in some developing countries. The growers of natural fibers are now looking for developing work in high- performance textiles to serve the places including air craft, space shuttle, health care, automotives, geo construction, transportation and physical protection.

It would undoubtedly be a factual approach to appreciate the significance of an enhanced value addition to produce textiles with an increased return for industrial development in general and for the betterment of country at large.

References

- Anon., Markets for technical textiles, Business Coordination House, Home page, www.bch.in , accessed June 24, 2008

- Seshadri Ramkumar; Appachi Arunachalam, India rising: Opportunities in nonwovens and technical textiles, Texas technical university, Texas (USA), pp1- 2.

- Reena Mital, Technical textile net, Home page, www.technical-textiles.net , accessed July 3, 2008.

- Ed., Faheem Uddin, BE textile design project, NED university of engineering and technology, 2005.

- Anon., G- suit, Home page, http://en.wikipedia.org , accessed June 26, 2008.

- Anon., Antigravity suit, The internet encyclopedia of science, Home page, www.daviddarling.info , accessed June 26, 2008.

- Anon., Airmanss world, Home page, www.af.mil , accessed June 26, 2008.

- Anon., Space suits, ILC Dover, Home page, www.ilcdover.com .

- D. Graziosi; J.Ferl; K. Splawn, Evaluation of rear entry system for an advanced spacesuit, SAE International (2005), pp 1- 2.

- D. Graziosi; W. Keith Splawn; Jinny Ferl; Amy J. Ross, Evaluation of the rear entry I- suit during desert RATS testing, ILC Dover, LP and NASA- Johnson Space Center, (2006), pp 1- 2.

- Anon., Parachute- Wikipedia, Home page, http://en.wikipedia.org , accessed July 2, 2008.

- Anon., Jet propulsion laboratory, Mars exploration rover mission, Home page, http://marsrovers.jpl.nasa.gov , accessed July 2, 2008.

- 18. W.P. Shepard son, Problems of parachute design and their relation to textiles, WADC, pp 3- 4.

- Anon., Lantal textiles, Home page www.aerospace-technology.com.

About the Author:

The author is associated with the Textile Department, School of Science of Technology, University of Management and Technology, Pakistan.