In terms of sustainability, Reicofil offers various approaches to save fossil raw materials, such as the processing of bio-based raw materials as an ecological alternative. For industrial applications, high-strength nonwovens can be processed even from up to 90 per cent polyethylene terephthalate (PET) flakes from post-consumer waste. This is how Reicofil shows ways to combine sustainability and high-performance nonwovens, the company said in a media release.

Reicofil also describes the so-called BiCo technology where two different raw materials are combined in one fibre in the spunbond process, creating a bimetal effect and causing the fibre to crimp. This opens the door for manufacturers to completely new product properties that are unattainable with monofibres, in the press release.

Moreover, with the c.Hub, the new data platform of the Reifenhauser group, Reicofil offers its customers a digitisation solution that is tailored to the requirements of nonwovens production. Customers can securely connect, centrally store and easily analyse data from their Reicofil machines, peripherals, ERP and MES systems via the c.Hub middleware. Together with various software bundles, c.Hub is offered as an on-premise solution. It can be deployed locally and remains under the full data sovereignty of the user. Via the web based ExtrusionOS user interface, customers can keep an eye on their production and the status of their machines wherever they are. The ExtrusionOS software packages offer transparency from the first to the last meter, faster defect troubleshooting, and complete traceability of key quality parameters.

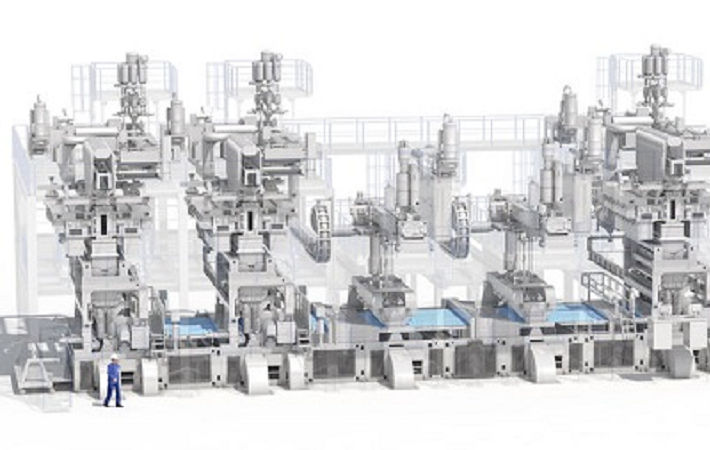

"We offer the appropriate line technology for almost any application. From soft and bulky high loft nonwovens, sustainable and bio-based fabrics to high barrier nonwovens with optimised properties and reliable filter characteristics to nonwovens made from post-consumer waste. With our current RF5 machine generation, we are also setting the benchmark in terms of quality, performance, availability, efficiency, and machine intelligence," Markus Muller, vice president sales & marketing, Reifenhauser group, said.

Fibre2Fashion News Desk (SF)