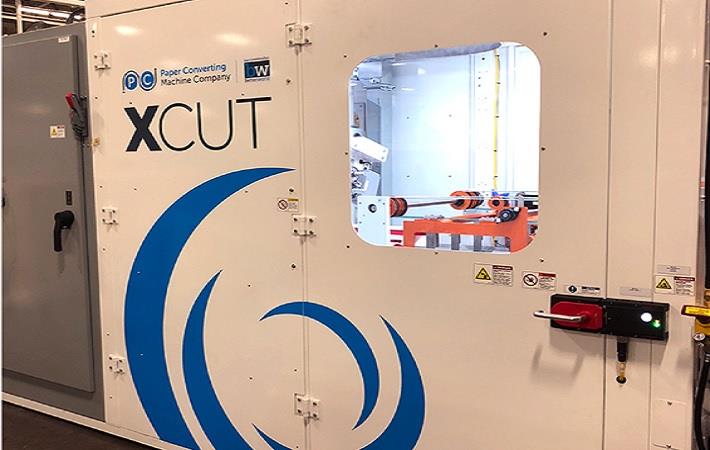

Paper Converting Machine Company (PCMC), part of Barry-Wehmiller, has announced that the Xcut saw, its newest tissue log saw, now has the ability to use predictive maintenance to reduce unplanned downtime. PCMCA manufactures high-performance converting machinery for the tissue, nonwovens, package-printing, and bag-converting industries worldwide.

With this new capability, operators will be able to track the lifecycles of critical components and monitor the performance of others. The saw will provide notifications regarding upcoming maintenance requirements before they become critical issues, allowing operators to have replacement parts ready when the time comes, according to PCMC.Paper Converting Machine Company (PCMC), part of Barry-Wehmiller, has announced that the Xcut saw, its newest tissue log saw, now has the ability to use predictive maintenance to reduce unplanned downtime. PCMCA manufactures high-performance converting machinery for the tissue, nonwovens, package-printing, and bag-converting industries worldwide.#

The Xcut saw will monitor and collect information from servo motor feedback, vibration sensors and other devices, and alert operators when the machine needs maintenance. For example, if an axis becomes more difficult to turn or experiences abnormal vibrations, the predictive maintenance system will provide an alert that the gearbox may need to be replaced.

This multifaceted approach to predictive maintenance allows operators to tackle multiple maintenance tasks at the same time, which reduces downtime and gets the machine back into production more quickly. “We want to give operators more control of their downtime. Predictive maintenance creates awareness ahead of time and lets operators plan ahead,” Jonathon Zahn, PCMC’s lead mechanical engineer for the Xcut said.

Fibre2Fashion News Desk (GK)