Teijin Frontier will begin selling its new polishing pads to manufacturers of semiconductors and flat-panel displays within the current fiscal year. It is targeting annual sales of one billion yen ($9 million) by the fiscal year ending in March 2026. Going forward, the company expects to expand its line-up of polishing pads in response to market needs by maximising the synergies of Nanofront polymer, polyurethane impregnation techniques, and abrasive fluids.

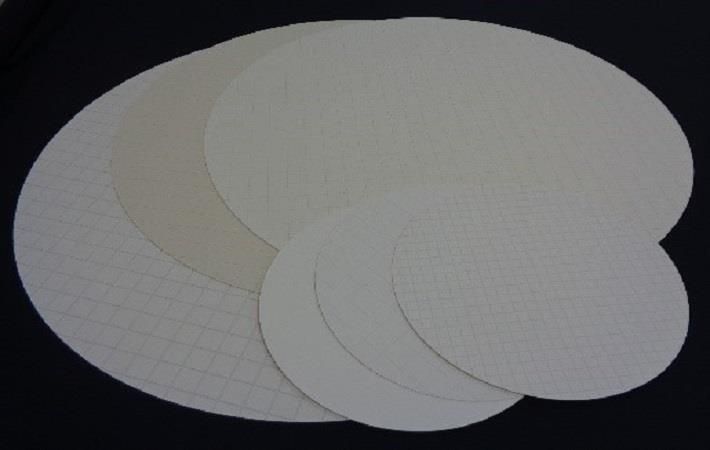

Demands are growing for semiconductors that offer higher performance and lower prices. To produce such semiconductors, polishing pads of different hardness are required. Polishing pads are used variously to enable nanometre wiring on semiconductor surfaces, to create mirror finishes that help to prevent crystal silicone damage, and to maintain silicon wafer quality characteristics. Reducing the amount of abrasive fluids without losing quality is a major challenge, but necessary to help lower silicon wafer manufacturing costs because the fluids account for a large portion of the costs. Teijin Frontier succeeded in development of new silicon pads realising both stable quality and reducing cost by adopting ultra-fine fibre Nanofront utilising its propriety yarn technology. (GK)

Fibre2Fashion News Desk – India