Braiding is more significant for industrial fabrics thanconsumer textiles and with its increasing applications, braiding is one of themajor fabrication methods for composite reinforcement structures, say DGopalakrishnan, Bhuvaneswari,

V Ramakrishnan

The limitations of the weaving, knitting and stitchingprocesses include poor shear resistance, limited strength in the primaryloading direction, and the inability to produce complex shaped parts. Theseshortcomings, as will be seen, are largely overcome with the adaptation ofbraiding. Braiding is a simple form of narrow fabric construction. It is doneby intertwining of yarns in whatever direction suited the maker's purpose. Thisbegan as a handicraft for the construction of decorative fabrics but thelimitations of knitting and weaving made braiding an important method of fabricformation in textile composite manufacturing industry.

Lace making, a domestic art of seventh century, is thebeginning of narrow fabric production. Increasing need for tapes in electricaluses, ribbons and laces made this handicraft into a leading industry. Themanual efforts were replaced by narrow width looms. There are definite trendstowards knitting by the crochet methods in some areas of narrow fabric production.For foundation wear, the trend is towards lighter-weight sheer garments so thatthe bindings should also be light weight, while, at the same time, fashiontrends have dictated that a variety of coloured yarns be incorporated in thesebindings. Crochet knitting machines have been found ideal for this purpose andhave replaced large numbers of traditional braiding machines.

Types

Braiding can be classified as two and three-dimensionalbraiding. Two-dimensional braid structure can be circular or flat braid.Three-dimensional braiding is relatively new and was developed mainly forcomposite structures. Although circular and flat braids have thickness, it issmall compared to the other two dimensions; therefore they are considered astwo-dimensional.

Two-dimensional braiding

Two-dimensional circular or flat braid is formed by crossinga number of yarns diagonally so that each yarn passes alternately over andunder one or more of the others. The most common designs in two-dimensionalbraids are as follows:

Diamondbraids: 1/1 intersection repeat.

Regularbraids: 2/2intersection repeat.

Herculesbraids: 3/3intersection repeat.

Circular braiding-mechanism

Circular (tubular or round) braids are formed hollow oraround a centre core. A circular braiding machine consists of two sets of aneven number of spools containing the braiding yarns. One set runs clockwisearound the centre of the machine and the other set turn in counterclockwisedirection. While revolving in opposite directions, the carriers are diverted topass alternately inside and outside (under and over) one another. The clockwiseand counterclockwise paths cause the two sets of yarns to intersect, thusproducing a tubular braid.

The yarns from the yarns are collected above the hub of thecircular track in which the bobbins travel. Circular braiders are called as"Maypole Braiders" since their motion is similar to the maypoledance.

References:

1. J.P. Turner: Textile Progress, the Production and Properties of Narrow Fabrics, Textile Institute, 1976.

2. Bernard P Corbman: Textiles Fibre to Fabric, 1983.

3. Sabit Adanur: Wellington Sears Handbook of Industrial Textiles, 1995.

4. Horrocus A R and Anand 5 C: Handbook of Technical Textiles, 2000.

5. D D Mungala, A E Bogdanovich and P W Duke: A Novel Process and Automated Machine for High-speed Three-dimensional Rotary Braiding, Textile Asia, August, 2005.

About the Author:

Mr. D. Gopalakrishnan is with Sardar Vallabhai Patel Institute of Textile Management, Coimbatore 641 004. Ms. Bhuvaneswari, Mr. V Ramakrishnan and Mr. T Sabarinath are with the Department of Textile Technology, PSG College of Technology, Coimbatore 641 004.

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow

this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp

Another type of braiding machine to produce two-dimensional braids is the rotary machine. The rotary braiding machine is faster than the maypole braider. However, rotary machines are less versatile in terms of making different shapes and they have less number of carriers.

Flat braiding-mechanism

Flat braids are made in the form of flat strips or tape. In flat braiding, instead of following two continuous paths, the carriers turn around or

Figure 1: Circular braiding-mechanism

reverse direction at two points called terminals and then continue on the other direction, i.e., the track does not complete a circle.

The size of the braid is governed by the following factors:

The number of carriers: tubular braiders have even number of carriers, and flat braiders usually have odd numbers of carriers. The minimum number of carriers is three, which gives the basic diamond braid similar to the girl's plaited hair.

The diameter of the yarn.

The number of yarn ends per carrier.

The number of yarns per unit length.

Take-up speed: Since the speed of the carrier is constant, the openness of the fabric is changed by changing the take-up speed of the fabric.

3-D braiding

3-D braiding is an interesting concept of creating a two dimensional array of interconnected 2-D circular braids. 3-D braids are formed on two basic types of machines. These are the horn gear and cartesian machines which differ only in their method of yarn carrier displacement. While the horn gear type machines offer improved braid speed over the cartesian machines, the cartesian machines offer compact machine size, comparatively low development cost and braid architectural versatility.

Horn gear braiding process

Horn gear machines with square or circular arrangement are employed in the fabrication of solid braids. Present-day machines are limited to 24 yarn carriers and therefore limit the size and shape of perform. The micro-geometry of braid is also restricted. The braider yarns form is intertwined helical paths through out the structure.

Cartesian braiding process

Figure 2: Horn gear braiding

Figure 3: Cartesian braiding

The basic Cartesian process involves four distinct Cartesian motions of groups of yarns termed rows and columns. For a given step, alternate rows (or columns) are shifted a prescribed distance relative to each other. The next step involves the alternate shifting sequence of the first and second steps, respectively. A complete set of four steps is called a machine cycle. It should be noted that after one machine cycle the rows and columns are returned to their original positions.

Braids

A braid is a rope like thing, which is made by interweaving three or more strands, strips, or lengths, in a diagonally overlapping pattern. They are used for various industrial applications. Made of different kinds of materials, such as cotton, polyester, nylon, plastic strands, etc, braids can be made in different thickness, lengths, etc. Primarily there are two kinds of braids.

Round Braids: Round braids have a round or oval cross section. The products made are cords (technique), laces (for clothes), cables (electro technique) or ropes (heavy braids).

Flat Braids: Flat braids are called laces or just flat braids. Braids have special characteristic features. Standard braids have only a low lateral stability. Due to this property they can be sewn to other textiles without problems. On the other hand they can be made rigid and stiff with inserts and after treatment. The load-bearing capacity of braided products is much higher as of products made with other techniques.

Geometry

Figure 4: Braiding geometry

The width L is called a line and the length S is called a stitch or pick. W is the width of yarn from which the braid is made. Braid structures are specified by the

line and stitch numbers. α is the braid angle, which specifies the angle by which the yarns lay from direction of machine axis. Braid angle is determined from the relation between the take-up speed and carrier speed.

Modern braiding machines

- Fast knit braiding machine Main features:

- Output: 2 cords.

- Yarn packages can be directly used.

- Any diameter from 2 mm to 12 mm can be produced on same machine.

- Construction of cords 4, 6, 8, 12 bobbins is possible on same machine.

- Density (picks/cm) in produced cord is adjustable in running of machine.

- Space saving, high speed and still quite in running.

- Power - 3 ph, Electric Motor - O.S.HP.

MODEL SM-6

Main features:

- Output 6: Cords.

- Diameter: 2 to 6 mm.

- Construction of cords: 4 or 6 ends.

- Other features similar to COMBI.

Extra attachments:

- Heat setting device.

- Rubber feeder for round elastic cords.

- Regulator for round elastic cords.

Automatic braiding system

In this system, braided preforms of composite tube are fabricated automatically and continuously. The system consists of a mandrel stock unit, a mandrel supply unit, braider units, a preform pick-up unit and a preform stock unit. A mandrel is supplied to the front of the braider units from the mandrel stock unit. Braided preform is fabricated on the mandrel when the mandrel goes through the multiple braider units. Braiding yarns are cut at the end of the mandrel after braiding. The preform is stocked in the preform stock unit.

These processes are carried forward automatically and continuously. Since the system has the multiple braider units, several layers or plies of fabric can be braided over each other to produce the required thickness in one process. Furthermore the fibre orientation angles are varied along the longitudinal direction on each layer, since each braider unit is controlled individually by using programme.

Narrow fabric

Narrow fabrics, sometimes referred to as 'small wares' are any textile fabric not exceeding 4S cm in width with 2 selvedges. Thus, narrow fabrics include any trimming, elastic, tape, ribbon, lace, cording and more.

Ribbons, tapes and webbings are all considered as woven narrow fabrics if they contain woven selvedges, and are less than 12 inches. They are woven on special narrow fabric looms, using the basic principle of warp filling interlacing. Several sets of warp yarns may be beamed together to make several narrow fabrics side by side, on the same loom. Some tapes and ribbons are prepared by cutting the full width fabrics into strips and sealing the

edges. Thermoplastic fabrics can be woven of this way.

Although, some shuttle looms are used, narrow woven fabrics are formed by needle looms. Because of the importance of a good selvedge, shuttle less looms are generally not used.

Materials used

Different kinds of narrow fabrics such as ribbons, laces, cords, tapes, labels, webbings, wicks, elastics, ropes, straps, trims, fringes and lanyards, etc may be crafted out of different kinds of materials such as leather, cotton, satin, velvet, polyester, Teflon, rubber, jute, nylon, fibre glass and also beads. Narrow fabrics are

usually decorative in nature but are often used in a large variety of home to add a decorative look to dresses and can also be attached to curtains; bed covers, etc and industrial applications.

Different kinds of materials used to make narrow fabrics are:

Cotton: The most practical and widely used medium, cotton is processed to make a highly decorative medley of

laces, wicks, tapes, webbings and lots more.

Figure 8: Automatic Crochet Machine

- Satin: Tapes, laces, & ribbons, etc made of satin look very luxurious.

- Velvet: Giving a velvety look & feel, narrow fabrics such as tapes are made from velvet.

- Polyester: The durable synthetic material is used to make different kinds of tapes, webbings, straps, etc.

- Teflon: Teflon is a popular material used for various kinds of tapes etc, for industrial applications.

- Rubber: Tapes made from rubber are widely used for different purposes.

- Jute: The 100% bio-degradable material is used to webbings.

- Nylon: Extremely durable & available in different colours & textures, nylon is made use of, for making high quality tapes, straps, etc.

- Fibre Glass: Wicks made of fiberglass are gaining popularity due to their chemical properties

- Beads: Trims, fringes made of shiny beads of different shapes and sizes are gaining popularity.

Modern narrow width fabric machines

Automatic crochet machine KYB609/8B

This Crochet machines is ideal machine for the production of laces, bands and ribbons, both elastic and non-elastic.

Mainly used for:

- For hosiery manufacture-bands, laces, elastic products.

- For shoe-making manufacture, shoe-laces, packing strings.

- For elastic industry, cables, conductors.

- For medicine, surgery threads.

- For everyday life, upholstering, curtains, sport, Alpine ropes, cords etc.

Standard delivery:

- Needle gap 15, 18.

- Pick repeat 48 picks.

- Weft and warp yarn stop motion system.

- 3 to 8 weft bars.

- Back frame.

- Low maintenance.

Optional parts:

- Back frame.

- Meter counter.

- Machine details:

- Pick repeat: 8-48.

- Max width: 50.

- Workstation width: 609.

- Motor: 1.5 HP.

- Max speed: 8001500 rpm.

Computerised jacquard needle loom (KYF JS6/45/192)

This high speed computerised jacquard needle loom represents the ideal machine to produce warp jacquard patterned rigid and elastic ribbons, articles for corsetry, ribbons for technical applications, etc.

Mainly used for:

- Narrow fabric and label weaving offers highest reliability even at highest speed.

- Woven selvedge applications especially because it can write two different working one per each head.

- High speed weaving of large area pattern.

Standard delivery:

- Choice of various weaving heads.

- Weaving elements with drive for weft needle, knitting needle, reeds and shafts.

- Jacquard unit includes jacquard cords, harness, comber board.

- Back frame.

- Weft and warp yarn stop motion system.

- Shed motion systems with pattern chain.

Options parts:

- Rubber feeding system.

- Beams.

- Meter counter.

- Computer design software.

Machine details:

- Model: KYFJS6!45!192

- Reed width: 45

- Heald frame: 8

- Pick repeat: 8-40

- Weft density: 3-40

- Hooks: 192

- Motor: 1.5 HP

- Max speed: 850 RPM

Fabric forming

Figure 9: Computerised jacquard needle loom.

(a) The sinker move out of their foremost position to the rear. The main bars complete their lapping movement. The latch needles begin to move upwards.

(b) The sinkers are inserted between ground inlay and pattern threads, which are guided and positioned exactly by the main bars. The needle latches start to open.

(c) The sinkers subdivide the ground inlay and pattern threads guided by the latch needles. The latch needles are open. The loops lie on the opened latches of the needles.

(d) The ground inlay and pattern threads guide by the main bars are now located underneath the heads of the needles, i.e., in the position determined by the pattern. The stitch-forming threads in the lower part of the guiding eyes belonging to the sinkers are passed between the ground inlay and pattern threads. They have now reached their highest position. The stitches lie on the shafts of the latch needles.

(e) The sinkers have taken up their rearmost position. The ground inlay and pattern threads guide by the main bars are held back of the latch needles by the stitch forming threads. The sinker perform a lapping movement over a needle space thus lay the stitch forming threads in the hooks of the latch needles.

(f) The sinker moves to front again. The stitch-forming threads are grasped by the hooks of the needles. The latter begin their downward movement and the main bars their lapping movement for the next row.

(g) The sinkers move further to the front. The latches of the needles are closed by the stitches. The main bars continue their lapping movement.

(h) The latch needles form new loops from the inserted stitch forming threads. The stitches are knocked over. The ground inlay and pattern threads guide by the main bars are fixed in their position by the stitch-forming threads. The sinkers continue moving in their foremost position.

End uses

Braided fabrics

Braiding is more significant for industrial fabrics than consumer textiles. Braiding is one of the major fabrication methods for composite reinforcement structures, with increasing applications of electrical wires and cables, harnesses, hoses, industrial belts and surgical sutures.

Examples of the relatively new application area of braiding include reinforcement structures of sporting goods (baseball bats, golf clubs, water skis, snow skis), aerospace and automotive parts. Because of the special properties, braids can be found (often hidden) in many different applications. Some examples: Clothes and shoes, candle wicks, sash cords, water ski ropes, mountaineering ropes, yachting ropes, parachute lines, fishing nets, mooring lines, medical applications such as catheters or dental floss, over braided high-pressure tubes, ground cables or harnesses

Components of textile stents

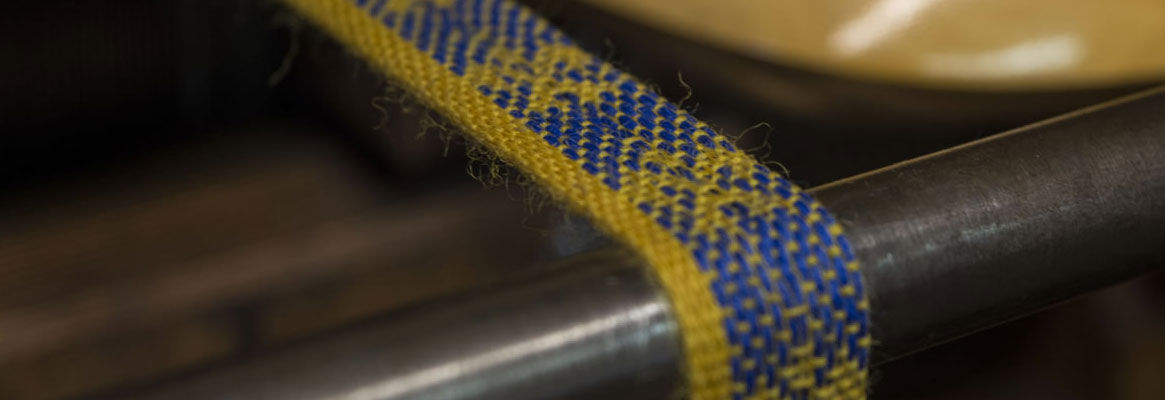

Braided and tubular narrow woven fabric sample.

Prototypes of 'textile stents' for endovascular implantation in humans, to replace commercially available metal stents. The prototype is an integrated braided and tubular narrow woven fabric assembly. The braided structure, manufactured with polyester monofilaments, acts as a reinforcing component and the tubular narrow woven fabric tightly covering it acts as a sealing component.

Osteosynthesis plates (commonly known as bone plates), widely used in orthopaedic surgery to heal fractured long bones, are generally made of stainless steel cobalt-chromium or titanium alloys. However, the high stiffness and poor fatigue characteristics of these metallic composites are not ideal for biomechanical harmony and promotion of bone healing.

By using braiding technology, bone plates made of braided carbon/PEEK composite have been developed.

Figure 10(a): Schematic drawing of an osteosynthesis plate fixed on the fractured long bone and (b) photograph of braided Carbon/PEEK composite osteosynthesis plate

Braiding technology was also applied to dental posts used in the tooth restoration process. The design requirement of stiffness change along the length was successfully achieved. This eliminates stress concentration at the root region-a problem commonly found with stainless steel dental posts. Translated into clinical benefits, it means that the dental post made by braiding technology can achieve a functionally graded post, which is more fracture-resistant, and can stay longer.

Prototypes of bifurcated polyester braided stents for abdominal aortic aneurysm.

Braided biodegradable scaffold made of nanofibre and the composite will be applied to develop tissue engineered blood vessel.

Figure 11: Biomimic composites applied for dental post

(a) Schematic drawing of a tooth treated by a dental post.

(b) Functionally braided post using braiding technique.

Narrow Fabric

Narrow fabrics are used for different purposes and find immense applications in various industries:

Prototype bifurcated braided stents

More tapes - Ribbon Tapes, Plain Tapes, Name Tapes, Jacquard Tapes, Elastic Tapes, Polyester Tapes, Reflective Tapes, Teflon Tapes, Rubber Tape, and Cotton Tape.

Ribbon Tapes

Ribbon tapes are very stylish and are available in various colour combinations and designs. These tapes are very soft and comfortable and are fabricated out of various fabrics such as nylon, satin, polyester satin, grosgrain, metallic, etc. They are used in webbing, decoration, belting for garment decoration accessory, gift wrapping and various other applications.

Ribbon tapes are available in a wide variety of materials, which include satin ribbon, grosgrain, check ribbon, organdy ribbon, dot printing, metallic organdy, print ribbon, velvet ribbon, string ribbon, flower ribbon, etc.

Plain Tapes

Plain tape is a tough weather and solvent resistant product designed to be sewn or welded to clothing. The product is available in a range of different widths and different colours. Plain tape finds a lot of usage for application to recreational products, e.g.: sports clothing, children's clothing, bags, etc.

Name Tapes

Name tapes, made from different kinds of fabrics have customised names on them. The names may be printed, embroidered or woven on the tape. These may be used for names of companies, on dog tags and military insignia. Usually, each custom name tape is produced individually and made-to-order.

They may be of the woven or iron-on variety. The electronically woven name tapes are available in many colours with fast lettering. The iron name tapes help identify and secure clothing, linen & toweling, etc. They are designed to remain permanently printed and once ironed on, they stay put.

Jacquard Tapes

The polyester or blended metallic jacquard tapes have floral, geometrical and whimsical patterns, and straight or serrated edges. The tapes may be hand-stitched at equal intervals, with single-strand dangling glass beads of various colours. These tapes may be manufactured to suit individual needs and production can be carried out on specific order. Jacquard tape may be available in a wide variety of colours, sizes, widths and patterns. They may also have embroidered or beaded designs on them.

Lace

Lace is made with a needle to form a series of loops, each one of which is finished with a fine stitch.

Parts of the lace

The patterns are constructed of different parts, each having a particular designation.

Bride, or reseau, is the fine yarn that forms the mesh which provides the sheer ground between the prominent parts of the pattern.

Cordon net is the heavy yarn that outlines the pattern.

Picot is a decorative loop used both in the pattern and on the edge of the lace.

Toile represents the predominant parts of the pattern made by braiding, knotting, looping, or twisting the yarns.

Classification

Allover lace has the design spread over the width of the fabric and repeated in its length. Many kinds of design motifs and colours are used. The fabrics can be produced in widths over one yard that are devoid of scallops and it comes in bolt form.

Flouncing comes in 12 to 36 inches. It has a straight top edge and is scalloped at the bottom.

Galloon has scalloped edges on the top and bottom. It comes in widths up to 18 inches.

Insertion may be sewn either between two pieces of fabric or to the top or bottom edge of a single piece of fabric.

Beading is a narrow gallon, inserting, or edging lace that has openings through which ribbon can be interlaced.

Edging comes in widths of 18 inches or less and has a straight top edge and a scalloped bottom.

Medallion is a single-lace design that is used as in applique on a ground fabric.

Special uses

- Garment industry

- Men's trunk tops

- Ladies lingerie

- Sports underwear

- Automotive Industry.

- Medical Uses

- Artificial Limbs

- Ankle and waist restraints

- Heavy suspender elastic

- Knee and elbow supports

- Lumbar belts

- Surgical Belts

- Safety Purposes

- Marine Industry

- Engineering & industrial products

- Industrial protective wear and accessories

- Packaging

- Lorry Lashing

- Work support belts

- Active Wear

- Tennis Shorts

- Jogging suits

- Swimwear

- Boxing jock straps Golf bags

- Wrist & knee supports

|

Types |

Usage |

|

Allover Lace |

Blouse, dresses and evening wears |

|

Flouncing |

Ruffles |

|

Edging |

Blouse, dresses and lingerie |

|

Medallion |

Blouse, dresses, napkins and lingerie |

Conclusion

Thus, the fabric forming mechanisms of braiding machine, crochet knitting machine, and needle looms and also end uses of braided and narrow width fabrics have been studied. This article focused on various end uses of braiding, needle looms, and narrow width fabric. These fabrics reveal properties, which are better than weaving and knitted ones in various aspects. The end uses vary over a wide range from decorative purposes top performance manufactures which are composite manufacturing. Scope of this manufacturing method can be extended by performing various testing methods for the produced fabrics, in terms of strength, stiffness, dimensional parameter, etc.