Introduction

With the rapid technologicaldevelopment and progress, human beings have accepted the challenge of workingin the increasingly hostile and adverse environment. Despite the growth of technology,work places still exist where we have to work in hot or/and humid conditions.Examples of such work areas include aerospace, firefighting, chemical warfareconditions, working in foundry and mines, working in arid/desert regions, etc.

Two stress generators actsimultaneously in such cases, work load and the hot environmental condition.People working in such conditions experience gradual increase in bodytemperature and find it difficult to achieve thermal equilibrium. Continuingwork in such uncomfortable conditions may lead to heat strain or even heatstroke, if necessary preventive measures are not taken.

Heat strain is the outcome of theheat stress, which occurs as heat input to the body surpasses the heatdissipation from the body. The resulting heat stress not only reduces theapparent thermal comfort and the work capacity but also encompasses the chancesof heat collapse. Studies have found the highest tolerable heat storage to be150 kcal, corresponding to a core body temperature of 40C.

Exposure to high temperatureduring working is a potentially fatal occupational hazard. Heat stressmanagement is a critical and sensitive area for protection of people who areworking in hot and/or humid environments. Regulation of core body temperature(Tc) is a very important aspect of heat stress management. Fromclinical point of view, Tc should be regulated in a very narrowrange of 36.7 0.3C. Thermal balance will be lost if Tc differs bymore than 2C on either side of 37C. While working in extreme hotenvironments, mostly a two way approach is adapted to control the core bodytemperature.

Firstly, a heat protective suit isworn by the worker which can act as a shield against the incoming radiativeheat from the hot environment outside. Unfortunately, such types of protectiveclothing impede dissipation of metabolic heat generated due to work. The secondapproach is to use cooling garments to remove this metabolic heat. Coolinggarments play an important role in alleviating the thermal discomfort

The operating principle of suchcooling garments is to create a cooler microclimate to facilitate the removalof metabolic heat and block heat exchange between the user and the environment.The cooling garments can be broadly classified in two groups based on theirworking principle, namely active and passive cooling garments. The operatingprinciple of active cooling garments is to circulate cold air or

10. McLellan, T.M. and Bell, D.G., Efficacy of air and liquid cooling during light and heavy exercise while wearing NBC clothing, Aviat. Space Environ. Med. 70(8), 802-811 (1999).

11. Arngrimsson, S.A., Petitt, D.S., Stueck, M.G., Jorgensen, D.K. and Cureton, K.J., Cooling vest worn during active warm-up improves 5-km run performance in the heat, J. Appl. Physiol. 96(5), 1867-1874 (2004).

12. Daanen, H.A., van Es, E.M. and de Graaf, J.L., Heat strain and gross efficiency during endurance exercise after lower, upper, or whole body precooling in the heat, Int. J. Sports Med. 27(5), 379-388 (2006).

13. Webster, J., Holland, E.J., Sleivert, G., Laing, R.M. and Niven, B.E., A light-weight cooling vest enhances performance of athletes in the heat, Ergonomics, 48(7), 821837 (2005)

14. Kinnman, J., Andersson, T. and Andersson, G., Effect of cooling suit treatment in patients with multiple sclerosis evaluated by evoked potentials, Scand. J. Rehab. Med. 32(1), 16-19 (2000).

15. Heim, A.M., Rothmaier, M., Weder, M., Kool, J., Schenk, P. and Kesselring, J., Advanced lightweight coolinggarment technology: functional improvements in thermosensitive patients with multiple sclerosis, Mult. Scler. 13, 232-237 (2007).

16. Syndulko, K., Jafari, M., Woldanski, A., Baumhefner, R.W. and Tourtellotte, W.W., Effects of temperature in multiple sclerosis: a review of the literature, J. Neurol. Rehabil. 10(1), 23-34 (1996).

17. Schutte, P.C., de Klerk, C. and Matesa, J., Body-cooling systems, Safety in Mines Research Advisory Committee, CSIR Mining Technology, 2002.

18. Kayacan, O. and Kurbak, A., Effect of garment design on liquid cooling garments, Text. Res. J. 80(14), 1442-1455 (2012).

19. Shim, H., McCullough, E.A. and Jones, B.W., Using phase change materials in clothing, Text. Res. J. 71(6), 495-502 (2001).

20. Craig, F.N. and Moffitt, J.T., Efficiency evaporative cooling wet cloth, J. Appl. Physiol. 36(3), 313-316 (1974).

21. Gibson, P.W. and Charmchi, M., Coupled heat and mass transfer through hygroscopic porous materials - Application to clothing layers, Sen-I Gakkaishi, 53, 183194 (1997).

22. Bumbarger, S.A., Bumbarger, T.H., Protective multi-layered liquid retaining composite. Patent 6371977 B1, USA, (2002).

23. Dewsbury, M.E., Market opportunities with superabsorbent fibers, Tappi J. February, 146 148 (1991)

About the Author:

The authors are associated with Department of Textile Technology, IIT, New Delhi.

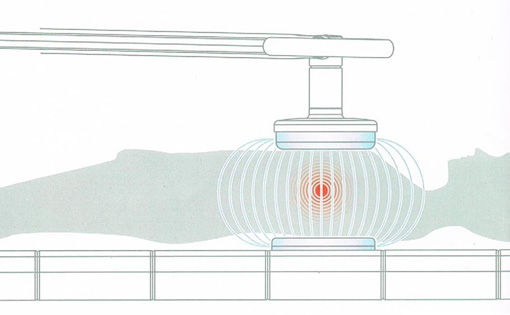

The cooling from evaporation of sweat is a very common phenomenon. Based on this principle, the evaporative cooling garments (ECGs) are developed where water is used as the evaporative liquid. The large latent heat of evaporation of water, 2430 kJ/kg at 30C, promises large cooling capacity. The concept of ECGs is to hold reserve water in the cooling garment, which will evaporate on receiving heat either from the body or from the outer environment. This will either raise the heat dissipation or reduce the heat input to body, resulting in a reduced heat stress.

Evaporative cooling garment

It has been shown that with the rise in ambient temperature the environmental heat will assist in evaporation, and thus will reduce the duration of cooling. Low level of humidity facilitates the evaporation process, whereas high amount of vapour concentration in the air constrains the evaporation process. The light weight of the laminate structure is one advantage for its use in cooling garments. The main weight load will be of water, whose volume depends on preferred cooling duration and environmental conditions.

The three layer quilted structure (Figure 1) consists of an absorbent core which is basically a nonwoven fibrous felt or batting, comprising of a typical blend of three types of fibre: cellulose, a cross-linked polyacrylate co-polymer (superabsorbent fibre) and polyolefin bonding fibre. The preferred composition of these three types of fibre in the nonwoven structure is 40% polyacrylate, 30% cellulose and 30% polyolefin. The nonwoven structure has a typical basis weight of 120 g/m2. Cellulose fibres help in rapid uptake of water as well as a quick release, giving an immediate cooling effect. The polyacrylate fibre is not as efficient in wicking as cotton, but it absorbs and retains a large amount of water. The strong hydrogen bonds in the polyacrylate fibre avoid draining of water from the structure due to gravity and releases water vapour at a steady rate over the period of time. On applying heat, the thermoplastic polyolefin fibres act as an adhesive binder for the other fibres to stabilise the nonwoven structure.

The inner moisture barrier layer is a woven fabric, which protects the wearer from dampness and provides a soft, draping surface for good thermal transfer between the wearer and the clothing. The inner fabric is inherently resistant to water and wind. The outer layer is a fabric which allows free passage of water vapour and limited passage of water. Suitable thread count and thickness of the inner and outer layer fabrics provide the required properties. No coatings or surface finish treatments are used for desired results. Garment assembly needs to be dipped in water for 1-2 minutes prior to use, in order to reserve the cooling liquid in the absorbent core of super absorbent polymer. Then the excess water needs to be rinsed and the cooling vests are ready for use.

The great advantage of this type of cooling garment is that it is light, flexible and therefore portable. But this type of garment is not suitable for humid conditions as because the effectiveness of evaporative cooling is inversely proportional to ambient relative humidity. Another limitation of this technology is cooling takes place on the outer surface of the garment, not inner surface which is nearer to skin. If evaporation rate is low, it may act as a thermal insulator and increase the thermal discomfort.

Super absorbent fibres (SAFs)

Super absorbent polymers (SAP) are hydrophilic networks that can absorb and retain a large amount of water in an aqueous solution. Most commonly available SAP in the market is partially neutralised lightly cross-linked polyacrylic acid, due to its best performance verses cost ratio. Water molecules are held in the hydrogel by means of hydrogen bond formation. Cross-linking between the polymer chains form a three dimensional structure and prevent infinite swelling, i.e. dissolving. Most of the SAPs are now made from acrylic acid (AA), its salt and acrylamide (AM) via solution or inverse-suspension polymerisation techniques.

Super absorbent fibres (SAF) are produced by Technical Absorbents Ltd. are basically sodium salt cross linked polyacrylates. Raw materials used for manufacturing of SAF are acrylic acid (AA), methyl acrylate (MA) and special Acrylate/Methacrylate monomer (SMMA) in which the acrylic acid is partially neutralised to the sodium salt of acrylic acid (AA Na). SAFs are normally not considered to be the main structural component due to two reasons: (1) its strength in dry state is not as good as other fibres of same denier and (2) the fibre changes its structure to a gel form after absorption. SAFs can be blended with other fibres and nonwovens from the can be processed by any dry-laid technology followed by bonding by needle punching, or thermal bonding, or chemical bonding. SAFs should be processed at 45% RH to 75% Rh for best performance.

Experimental study

For designing the three layer evaporative cooling fabric assembly, the inner layer (which is nearer to skin) is made from some commercially available water repellent breathable fabric. Evaporative resistance of the inner layer fabric was measured as per ASTM F186812 standard on Sweating Guarded Hot Plate. The fabric has an evaporative resistance value of 12.329 Pa.m2/W. The outer layer fabric is woven from 150/96 denier multifilament yarns with varying warp thread density and weft thread density to achieve different air permeability values. Prior to weaving the 150/96 denier multifilament yarn was twisted at 316 twist per meter to avoid the problem of filamentation during weaving. Air permeability of the outer layer fabrics was measured as per ASTM D737 04(2012) standard on Textest FX 3300 instrument.

Three layered assembly with a needle punched fabric contains 37.5% of SAF and remaining polyester, with basis weight of 210 g/m2 as absorbent core was used in the experiments.

To study the effect of different SAF content, basis weight and thickness of the absorbent core on protective performance thermal bonded nonwoven structures were made from the following design matrix as shown in Table 1. To prepare the thermal bonded nonwoven structures 20% low melt polyester fibres were blended with the normal Polyester and SAF. Cross-lapped web of different basis weight were made from DILO needle punching machine. The cross-lapped web was then thermally bonded in compression moulding machine at a temperature of 130C for 20 minutes to obtain the final structure. To achieve different thickness metal frames of different thickness were used in between the top and bottom heating plate.

Table 1: Design matrix for designing the absorbent core.

Super absorbent fibres of 9 denier and staple length of 52 mm were used. The three layer evaporative cooling fabric was made by stitching the outer layer, absorbent core and inner layer together on a lockstitch machine. Sewing thread used was of 270/2 denier and stitch density was kept to 3 stitches/cm. Sample size of 18 cm12cm was used for testing. The structure of the three layer evaporative cooling fabric assembly is shown in Figure 2.

The fabric assembly was exposed to heat flux from a radiant heat source. Time to reach 45C (threshold pain temperature at skin) has been considered to be evaluation criteria of the protective performance.

Effect of addition of water on protective performance

To study the effect of addition of water to the sample on its performance, tests were carried out at 1.0 kW/m2 in three conditions: without any fabric assembly, with dry fabric assembly and with wet fabric assembly. The absorbent core was the needle punched nonwoven fabric of 210 g/m2 basis weight, containing 37.5% SAF. Outer layer used in this study was a commercially available plain woven polyester fabric having thread density of 3071 ends/m and 3145 picks/m. The dry fabric sample weight was 14.76 g and it absorbs 94.9 g of water after 15 minutes of immersion in water. In Figure 3, temperature at the back of the sample or at the inner layer is plotted with time.

Figure 3: Time vs. temperature plot at 1.0 kW/m2 with dry fabric, with wet fabric and without fabric

From Figure 3, it can be observed that for any given time period, the temperature increase is highest for tests without any fabric. After test duration of 1 hr, sensor temperature reaches 94C for test condition without any fabric. The dry thermal insulation of fabric sample prevents some amount of heat from reaching to the sensor. So, after same duration the temperature at the back of the dry sample is 57C and for the wet sample is 48C. Although addition of water increases the thermal conductivity of the sample, the phenomena of evaporation of excess water act as buffer between the heat source and sensor, thus preventing more amount of heat from reaching the sensor. As a result temperature increase at the back of the sample is lesser in case of wet fabric as compared to the dry one. Addition of water helps in improving the performance of the fabric assembly.

For the wet fabric the temperature almost stabilises after 1hr of experiment, whereas, for dry fabric it continues to increase. The reason for this is that the total amount of incoming heat being used for evaporation. Thus little or no heat is reaching to the sensor and the temperature remains almost stable at 48.0 0.5C. Once the sample dries up completely, the temperature again starts to increase. At the initial stage some amount of heat reaches the sensor and the rest is used for evaporation. Rate of evaporation at this stage is also slow. For this reason, temperature rise is observed in the initial stage of the experiment.

Comparison of needle punched Vs. Thermal bonded structure

A comparison was studied between a needle punched structure and a thermal bonded structure containing 20% SAF, having a basis weight of 200 g/m2 and thickness 4 mm. The needle punched structure was made on DILO needle punching machine and punch density was kept 60/cm2. Figure 4 shows the result obtained at 1.0 kW/m2 heat flux. Thermal bonded structure shows better performance than the needle punched structure. Time required to reach 45C is 3.22 hrs for the thermal bonded structure and 2.28 hrs for the needle punched structure. The reason may be the presence of holes created by the needles in the needle punched structure. We can consider the holes to be water channel when the samples are in wet condition. Thus helping in quicker heat conduction and increases the rate of evaporation, resulting in poorer performance of the needle punched structure.

Effect of SAF content on protective performance

To study the effect of SAF content on protective performance, thermal bonded nonwovens were made of basis weight 200 g/m2 and thickness 6 mm. SAF content in the nonwovens were 10%, 20% and 30%. Amount of water added was 400%. Tests were carried out at 1.0 kW/m2. Figure 5 shows the effect of increasing SAF content. With the increase in SAF content, chances of water being absorbed by SAF increases. The incoming heat has to first break the hydrogen bond between the SAF and water molecules and then evaporate the water. So, higher amount of energy is required than normal evaporation. As a result amount of heat reaching the sensor decreases and time required to reach 45C increases.

Effect of Basis weight of absorbent core on protective performance

To study the effect of basis weight of the absorbent core on protective performance, thermal bonded nonwovens were made of SAF content 30% and thickness 6mm. Basis weight used were 100, 150 and 200 g/m2. Amount of water added was 400%. Tests were carried out at 1.0 kW/m2. Figure 6 shows the effect of increasing basis weight. With the increase in basis weight amount of water added increases, resulting in a better performance.

Effect of thickness of absorbent core on protective performance

To study the effect of thickness of the absorbent core on protective performance, thermal bonded nonwovens were made of SAF content 20% and basis weight 200 g/m2. Thickness of the absorbent core was varied from 4 mm to 8 mm. Amount of water added was 400%. Tests were carried out at 1.0 kW/m2. Figure 7 shows the effect of change of thickness.

With the decrease in thickness, the structures become more compact. Contact points among the fibres can be considered to increase, making the pores more torturous. Rate of evaporation from a compact structure is relatively slow as compared to an open one. Slow evaporation will provide prolonged performance. Lower thickness resulting in denser fabric shows better performance as compared to low density thicker fabrics.

Conclusion

Nonwoven fabrics containing Super Absorbent Fibres can be used to increase the protection time against heat. Protective performance of assembles containing nonwovens as absorbent core has been evaluated. A number of three layer evaporative cooling fabric assemblies were designed and effects of various parameters on its performance were studied. Adding of water to the sample provides better performance than the dry sample due to evaporative cooling. Neither too high nor too low amount of added water provides satisfactory performance. Optimum performance was obtained when the amount of added water was four times the dry weight. Too tight or too much open construction of the outer layer also does not facilitate the cooling process to satisfactory level. Increasing the SAF content and basis weight of absorbent core has positive effect on the protective performance, whereas increasing the thickness of the core decreases the performances. Evaporative cooling garments can be designed using different amount of SAF and different basis weight depending on the end user requirement. Same level of performance can be achieved by using lower basis weight and higher SAF content as compared with higher basis weight and lower SAF content, but cost of the product will increase.

References:

1. Nunneley, S.A., Water cooled garments: A review, Space Life Sci. 2, 335-360 (1970).

2. Webb, P., Measuring the physiological effects of cooling, Human Factors, 13(1), 65-78 (1971).

3. Schneider, J., Identification and management of thermal stress and strain, In: Queensland Mining Industry Health and Safety Conference Proceedings, 195-201 (1999).

4. Taylor, N.A.S., Challenges to temperature regulation when working in hot environments, Industrial Health 44, 331-344 (2006).

5. Hexamer, M. and Werner, J., Control of liquid cooling garments: Technical control of body heat storage, Applied Human Science: J. Physiol. Anthropol. 15(4), 177-185 (1996).

6. Nag, P.K., Pradhan, C.K., Nag, A., Ashtekar, S.P. and Desai, H., Efficacy of a water cooled garment for auxiliary body cooling in heat, Ergonomics, 41:2, 179-187 (1998).

7. Cowell, S.A., Stocks, J.M., Evans, D.G., Simonson, S.R. and Greenleaf, J.E., The exercise and environmental physiology of extravehicular activity, Aviat. Space Environ. Med. 73(1), 5467 (2002).

8. Webb, P., Troutman, S.J. and Annis, J.F., Automatic cooling water cooled space suits, Aerosp. Med. 41(3), 269 (1970).

9. Chen, Y.T., Constable, S.H. and Bomalaski, S.H., A lightweight ambient air cooling unit for use in hazardous environments, Am. Ind. Hyg. Assoc. J., 58(1), 10-14 (1997).