Braiding, both two-dimensional and three-dimensional, is popular in the manufacture of industrial ropes, fabrics and structures for composite application, says Pradeep Kulshrestha.

The technique is relatively simple and age-old, but the results are impressive.

Braiding is carried out in medium scale companies mostly on indigenous machines. The photograph below shows the machine from Susmatex Rope Braiding Machine at Hirpara Technical Textiles, Ahmedabad.

Creeling of yarn as per planned diameter of rope on braiding machine is done:

a) To insert individual ends in needles

b) To adjust settings

c) Complete the braiding

There is demand for industrial ropes for the marine industry, mountain climbing, yachting ropes, parachute lines, fishing nets, mooring lines, medical applications such as catheters and for dental floss. Research is on to develop high strength ropes.

These are needed for heat protection and thermal resistant applications also. These ropes are being developed by technical fibres like nylon glass, aramid and dyneema.

Fibre glass generally consists of extremely fine glass fibres used to manufacture fabric and structural objects for composite applications.

Carbon fabric is generally used in applications such as brake linings, aircraft interiors, windmill blades, tooling, primary and secondary structures. Carbon fibre provides maximum stiffness in aircrafts.

Braiding is a method of interlacing three or more threads in such a way that they cross one another in diagonal formation. Flat, tubular and solid products may be developed in this process.

Some braiding machine manufacturers are:

1. Braid Solutions, Faridabad, India

2. Taiwan Braiding Machine Manufacturers, Taiwan

3. Herzog Braiding Machine, Germany

4. Karl Mayer, Germany

5. Wuxi Longterm MachineryTechnologies Co., Ltd, China

6. United Textile Machinery Corporation, USA.

Of these, Wuxi has a range of different machines like braiding machine, lace braiding machine, rope braiding machine, and computerised lace braiding machine.

Radial braiding machine:

Radial braiding machine type RF 1/128-100

-

128 carriers

-

Bobbin 55 x 170 x 130 mm = 265 ccm

-

Motor power: 4 x 0,55 kw

-

Speed: 150 r. p. m.

Recommended for the production of 2 1/2 D carbon fibre and glass fibre products. Special bobbins are required for braiding clock-wise and anti-clock wise.

Types of carbon fibre:

Significance of different carbon fibres available:

|

K |

Tex |

Denier |

No. of Filaments |

|

1 |

70 |

630 |

1000 |

|

3 |

200 |

1800 |

3000 |

|

6 |

400 |

3600 |

6000 |

|

12 |

800 |

7200 |

12000 |

|

24 |

1600 |

14400 |

24000 |

|

50 |

3300 |

29700 |

50000 |

Test report of some carbon fibres:

|

Test Parameters |

Units |

Test Method |

Test Result (3 K) |

Test Result (12 K) |

Test Result (50 K) |

|

Single carbon fibre diameter |

Micron (mm) |

Projection Microscope |

8.0 |

8.0 |

8.0 |

|

Single carbon fibre strength |

cN |

Fafegraph -M |

7.98 |

12.0 |

8.05 |

|

Single carbon fibre elongation |

% |

Fafegraph -M |

4.15 |

3.31 |

2.38 |

Selection of Aramid:

|

Company |

DuPont Kevlar |

DuPont Kevlar |

DuPont Kevlar |

|

Style |

802F |

745 |

258HPP |

|

Product Specification |

190 g/m2 |

450 g/m2 |

410 g/m2 |

|

Denier |

1000 |

3000 |

3140 |

Properties of radical braiding machine:

|

Properties |

Facilities |

|

Improved mechanical and structural properties |

2 1/2 D Radial Braiding Machine |

|

Ability to form a variety of complex shapes |

176 carriers |

|

Manufacturing complex structural shapes |

Bobbin: 76 X 80 X 280 mm |

|

High torsional stability and structural integrity |

Motor power: 4 X 0.55 kW |

|

Braid high functional fibers: Aramid, Carbon, PP etc |

Speed: 150 rpm |

Braiding complex structures with carbon

Carbon braided lightweight bicycle

Among the various braided

structures, biaxial and tri axial two dimensional (2D) braided structures have

been applied in various technical sectors. Techniques to develop such

structures are well developed compared to 2D braided structures while 3D

braided structures contain multiple layers and are highly suitable for

producing complex geometries. Cost effectiveness and capability of producing

complex shapes makes braiding popular in composite applications.

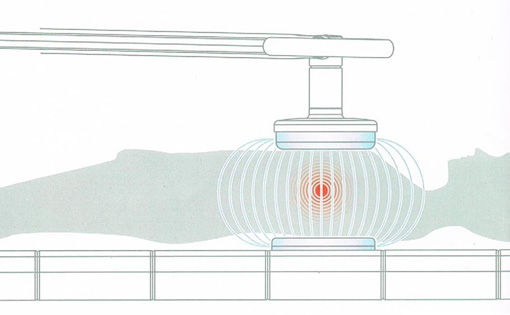

The robotic radial braiding

machine is the first of its kind in India developing automobile related

composite materials.

Reference:

1. Advances in Braiding Technology

by Yordan Kyosev

2. International Aerospace

Abstracts - Volume 36 - Issue 4. 1996

3. ATIRA - Ahmedabad (Robotic

Radial Braiding Machine)

4. Shanghai Henghui International

Company Limited (Mainland), Shanghai

5. Exhibition at ITMA ASIA + CITME

2014, Shanghai

6. Technotex India Exhibition,

Mumbai

7. Hirpara Technical Textiles

Limited, Ahmedabad

About the

author:

Pradeep Kulshrestha is an experienced professional in Textiles Operations Management. He has over 30 years of experience in administering world class manufacturing plants and project implementation.