Lotus, the radiantly graceful aquatic plant that hasplayed a vital role in many religions and cultures is now a source ofinspiration to nanotechnology.

Things of nature are clean by itself. There are no janitorsin the woods, dusting the trees. While people use various cleaning treatments,nature applies an environmentally benign cleaning strategy. Drops of water onthe lotus leaf shine with a sparkle, washing away the dirt from it more swiftlythan any other plant. Nature has always been a source of positive inspirationto man. Researchers observed that wax and microscopic bumps on the surface ofthe leaf makes it to repel water. Water droplets rolling down from the lotusleaf collects the dirt particles and small insects on the top of the leaf, andeffectively cleans the surface. Lotus leaves, through a complicated micro-tonano surface structure, repel dirt, and water. They found the means totransform nature into technology which gave way for the making of selfcleaning, and soil, & water repellent textiles.

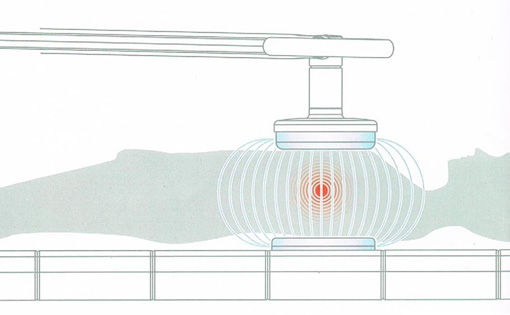

The traditional techniques demonstrated good effects butwere not durable under conditions of intense use. Chemicals were used in theearly 90s to exhibit water repellent character followed by wax later. Chemicallytreated fabrics became harsh and also resulted in a discoloration. Furthermore,there was no wash durability. The new approach has minimized the shortfalls ina significant way. Self cleaning and super hydrophobic micro to nano structuredsurfaces was observed in some plants. A nano-structured surface is created withsuper paramagnetic nano particles. This ferromagnetic fibre structuring withhigh energy magnetic field coil takes place after the spinneret, when thespin-melt is in a thermoplastic state, which allows for the stretching offilament.

Applying the lotus effect to textiles is not easy. The process of coming up with a hydrophobic surface is a challenging job. The material that repels everything has to be made to stick with the fabric. Basic principle of water repellent is the force of surface tension. When water falls over a normal fabric, it spreads over the fabric surface, making it wet. On the contrary, a drop of water on the surface treated fabric will remain as such, and roll down when tilted. The water drop is not absorbed by the fabric. The treated fabric can withstand not only water, but also other liquids such as coffee, tea, red wine, edible oil, ketchup etc.

Lotus effect has foresees a wide variety of beneficialtextile applications in suiting, coats, furnishings, trousers, shower curtains,table covers etc. Fluorocarbon based fabrics are used in making sportswear, andindustrial workwear. It is suggested that the fabric should be ironed or tumbledried. Heat treatment is required to restore the repellent effect.

This new technology indicates new ventures in the field of smart textiles. A lotus leaf does not collect any dirt, but a string of ground-breaking, and useful innovations.

References:

- Fluorocarbon (water repellant) finish in textiles, Indian Textile Journal, September 2010.

- A new approach optimizes lotus effect of soil repellent textiles, Bangladesh Textile Today, July-August 2010.

- &sec=article&uinfo=<%=server.URLEncode(2945)%>" target="_blank" class="MsoNormal" style="text-align:justify">http://www.indiantextilejournal.com

- &sec=article&uinfo=<%=server.URLEncode(2945)%>" target="_blank" class="MsoNormal" style="text-align:justify">http://www.lotus-effekt.de

Image Source:

- picsdigger.com

- wired.com

- spray-shop.co.uk