Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

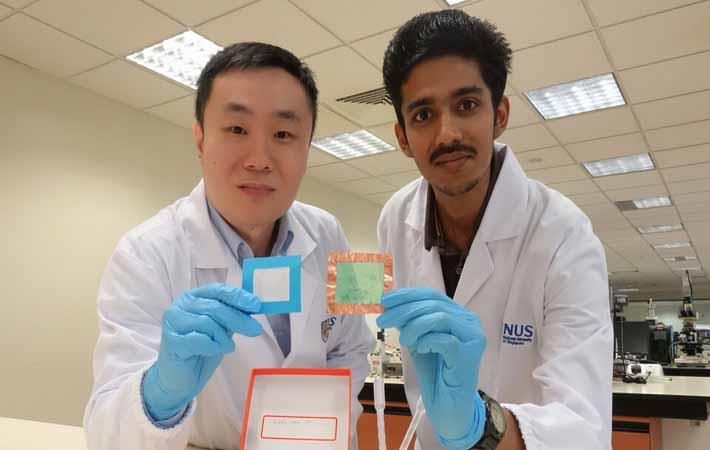

The research has been done by researchers at the National University of Singapore. Overall, the air filters developed using the novel nanofibre solution are two times better in quality than commercial ones, and are suitable for applications on windows and doors to improve indoor air quality. These also have promising applications in respirators.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

"Air pollution poses serious health threats. Therefore, there is a strong need for economical and effective technologies for air filtration. Currently, most nanofibres used in air filters are energy intensive to produce and require specialised equipment. Our team has developed a simple, quick and cost-effective way of producing high-quality air filters that effectively remove harmful particles and further improves indoor air quality by enhancing air ventilation and reducing harmful UV rays," explained Assistant Professor Tan Swee Ching from the department of materials science and engineering at the NUS faculty of engineering, who led the research.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

"In the long run, it may even be possible for a DIY (do-it-yourself) kit to be made available commercially for consumers to make air filters at home," the scientist said.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

The team also included Indian origin scientists Sai Kishore Ravi and Dr Varun Kumar Singh. The study has been published in the online version of scientific journal, Small.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

The scientists have filed a patent for the invention and are working to add anti-bacterial properties into the air filter. The efforts are on to find industry partners to commercialise the technology.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

According to the team, the air filter developed is eco-friendly and easy to produce, simply by applying the novel nanofibre solution onto a nonwoven mesh, and leaving it to dry naturally. Using phthalocyanine, a chemical compound commonly used in dyeing, the NUS team engineered organic molecules that could self-organise, similar to the stacking of building blocks, to form nanoparticles and subsequently, nanofibres. These nanofibres, which exist in the form of an organic solution, easily "cling" onto the nonwoven mesh when dispersed onto the material.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

Air filters are generally gauged by a parameter called quality factor, which is dependent on two sub-factors - particle filtration efficiency and air permeability. Currently, while commercial respirators have a high particle filtration efficiency, air permeability is considerably low, thus resulting in a low quality factor.

Scientists in Singapore have created a novel nanofibre solution that creates thin, see-through air filters which remove up to 90 per cent of PM2.5 particles and achieve high air flow of 2.5 times better than conventional air filters. The eco-friendly air filter also improves natural lighting and visibility while blocking harmful ultraviolet rays.#

The new air filter achieves a quality factor of about two times higher than commercial respirators. It can filter up to 90 per cent of hazardous particles that are less than 2.5 microns in size, also known as PM2.5 particles and associated with serious health threats, while maintaining air flow that is 2.5 times better than these respirators, resulting in better breathability. The particle filtration efficiency can be further enhanced, depending on the purpose and functionality of the air filter. (SV)

Fibre2Fashion News Desk – India