Scientists from around the world have developed a simple metallic coating treatment for clothing or wearable textiles which can repair itself, repel bacteria from the wearer and even monitor a person’s electrocardiogram (ECG) heart signals.

Researchers from North Carolina State University, Flinders University and South Korea say the conductive circuits created by liquid metal (LM) particles can transform wearable electronics and open doors for further development of human-machine interfaces, including soft robotics and health monitoring systems.

The ‘breathable’ electronic textiles have special connectivity powers to ‘autonomously heal’ itself even when cut, said the US team led by international expert in the field, professor Michael Dickey.

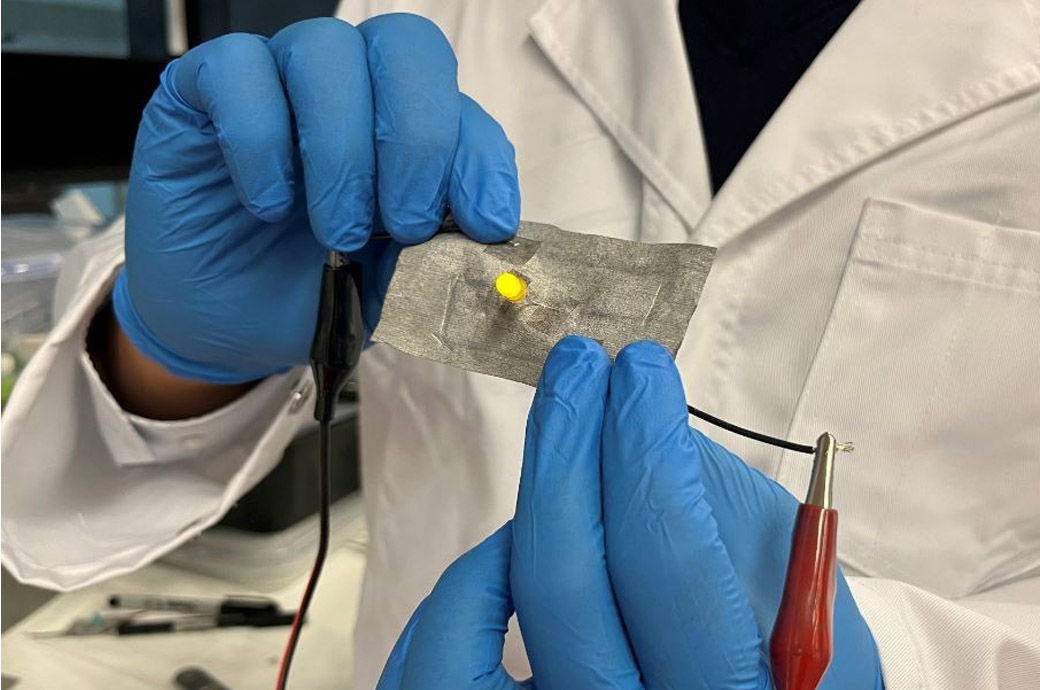

When the coated textiles are pressed with significant force, the particles merge into a conductive path, which enables the creation of circuits that can maintain conductivity when stretched, researchers say.

“The conductive patterns autonomously heal when cut by forming new conductive paths along the edge of the cut, providing a self-healing feature which makes these textiles useful as circuit interconnects, Joule heaters and flexible electrodes to measure ECG signals,” said Flinders University medical biotechnology researcher Dr Khanh Truong, senior co-author in a new article in Advanced Materials Technologies.

The technique involves dip-coating fabric into a suspension of LM particles at room temperature. “Evenly coated textiles remain electrically insulating due to the native oxide that forms on the LM particles. However, the insulating effect can be removed by compressing the textile to rupture the oxide and thereby allow the particles to percolate. This enables the creation of conductive circuits by compressing the textile with a patterned mold. The electrical conductivity of the circuits increases by coating more particles on the textile,” the report said.

The LM-coated textiles offer effective antimicrobial protection against Pseudomonas aeruginosa and Staphylococcus aureus. This germ repellent ability not only gives the treated fabric protective qualities but prevents the porous material from becoming contaminated if worn for an extended time, or put in contact with other people.

The particles of gallium-based liquid metals have low melting point, metallic electrical conductivity, high thermal conductivity, effectively zero vapour pressure, low toxicity and antimicrobial properties.

LMs have both fluidic and metallic properties so show great promise in applications such as microfluidics, soft composites, sensors, thermal switches and microelectronics. One of the advantages of LM is that it can be deposited and patterned at room temperature onto surfaces in unconventional ways that are not possible with solid metals.

Fibre2Fashion News Desk (RR)