Thus, Toray Carbon Fibers Europe now has the ability to reduce the Life Cycle Inventory (LCI) of its carbon fibre, prepreg, and other offerings and help its customers to enhance product Life Cycle Assessments (LCA) while contributing to building a circular economy.

The ISCC PLUS, International Sustainability & Carbon Certification’s (ISCC), a voluntary certification programme, guarantees that the raw materials used are sourced from biomass or recycled materials. It also ensures that there is complete traceability at all stages of the manufacturing process of a product. The mass balance approach tracks the amount and sustainability characteristics of circular and bio-based materials used in the value chain and it is based on verifiable records. This scheme is open to several sectors such as the food, feed, chemicals, plastics, packaging and textile industries, the company said in a press release.

Toray Carbon Fibers Europe will start manufacturing carbon fibre derived from biomass and recycled raw materials by the end of 2023. In addition, Toray’s Ehime Plant in Japan aims to obtain ISCC PLUS certification by March 2024 and begin producing fibre by the close of that year. In the US, the carbon fibre facility of Toray Composite Materials America in Decatur, Alabama, also plans to obtain this certification in 2024. With these three locations obtaining certification, the Toray Group intends to manufacture carbon fibre using biomass or recycled raw materials at plants in Japan, the United States, and Europe, ensuring stable supplies to customers around the globe.

Toray has already received requests from customers similarly committed to carbon neutrality. From the end of 2023, Toray will offer this carbon fibre for industrial applications such as automobiles and handheld devices where demand for materials to create sustainable products is particularly high. At a later date, other applications, such as aviation and sports, will also be targeted.

This effort aligns with the Toray Group’s carbon fibre composites business roadmap to achieve carbon neutrality by 2050. Under Project AP-G 2025, its medium-term management programme, Toray is actively contributing to the development of a more sustainable economy by quantifying the LCA improvements of customer products, reducing the LCIs of carbon fibre, prepreg, and other offerings, and using and recycling bio-based materials as part of its new materials ecosystem.

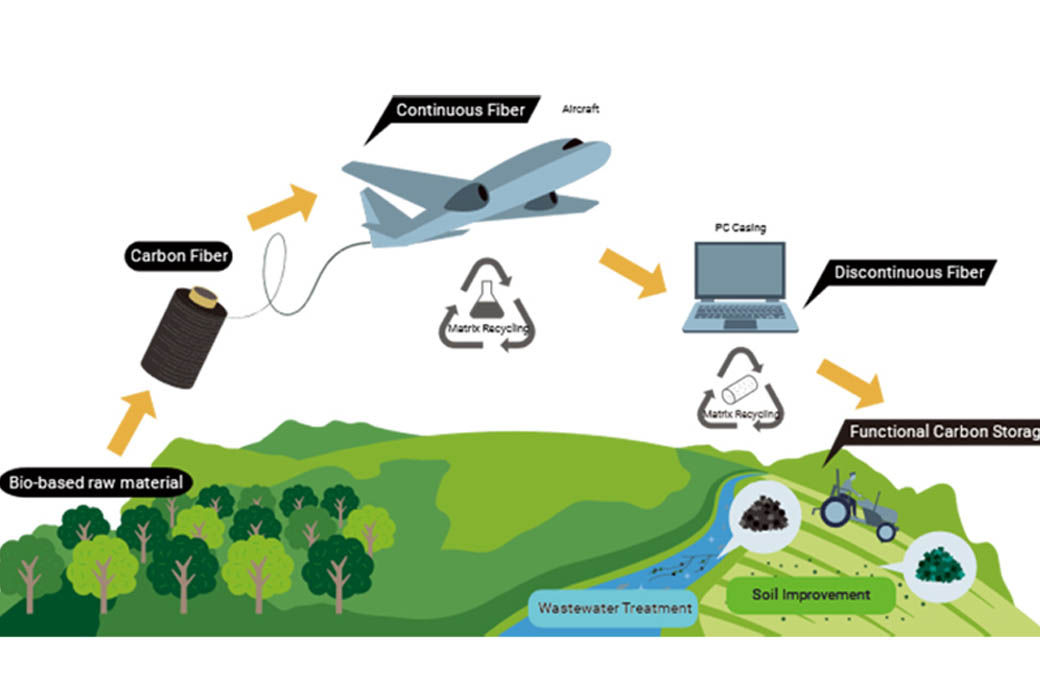

Toray aims to build a new materials ecosystem that harnesses natural raw materials and returns them to nature in an eco-friendly state. For carbon fibre, the ecosystem will be built using biomass and recycled raw materials to manufacture carbon fibre. This fibre will be made into a composite material and, finally, an end product. At the end of the product’s life cycle, continuous carbon fibre will be repurposed for the use as discontinuous fibre in other products. The last stage of the carbon fibre’s life cycle will be its recycling for water treatment or soil improvement.

Fibre2Fashion News Desk (RR)