In the creation of the Durapontex N-Series, DSC maintains precise control over the supercritical foaming environment. Nitrogen gas emissions are infused, leading to an innovative transformation. As result, a soft foam cell is made with consistent room between the bubble-like cells, creating an ultra-lightweight insole that delivers high resiliency and rebound, DSC said in a press release.

DSC also makes use of supercritical foaming technology to create the enhanced upper composite material, resulting in a foam composite so thin that it can be sliced in slim dimensions under 1.8mm.

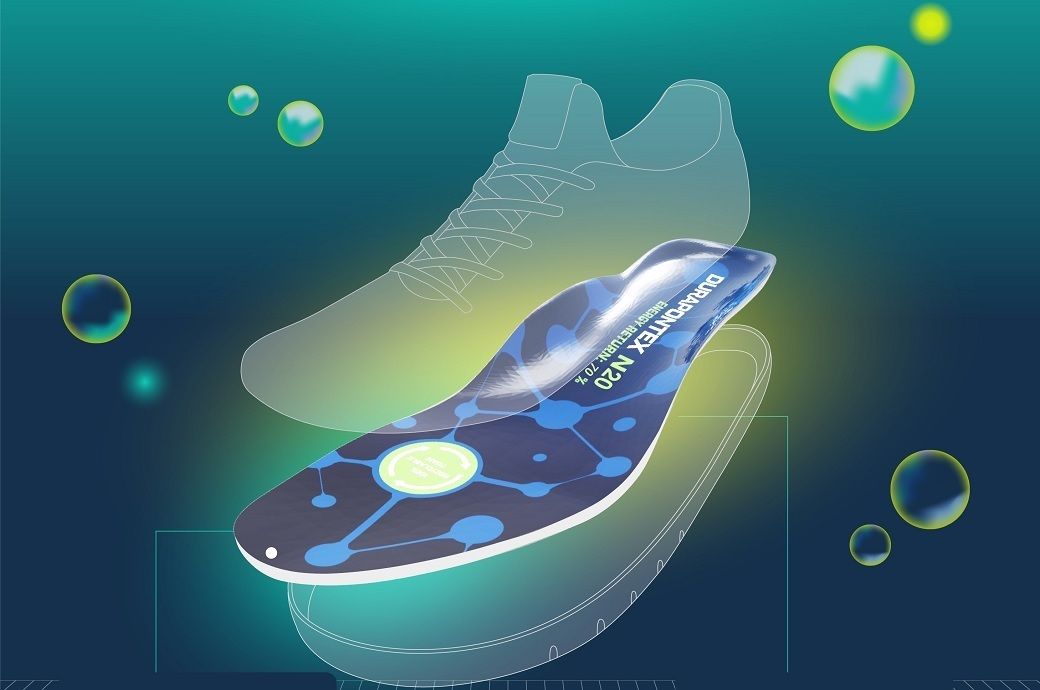

The Durapontex N-Series offers a range of options with various densities and rebounds, including the Durapontex N20 and the Durapontext N23. The Durapontex N20 tips the performance scale, boasting a low-density performance of 0.05+/- 0.02. DSC will demonstrate the rebound capabilities of the N20 at the NE and NW Materials Shows, with a consistent maximum resiliency of 70 per cent, added the release.

In line with DSC’s commitment to sustainability, the N-Series foam is 100 per cent recyclable. A desire to create eco-innovation is a catalyst for DSC, as well as paving the way toward its sustainable business plan, Run the Relay. DSC’s existing sustainable product range includes, Dreamcell Zero, made with 100 per cent recycled foam waste, as well as innovations such as Dreamcell Xpresso. The Dreamcell Xpresso insole is made with 20 per cent spent coffee grounds, decreasing the amount of fossil fuels, waste, greenhouse gas emissions, and energy in the production process.

Johnson Chang, CEO of Dahsheng Chemical, said: “The DSC innovation team has achieved a significant milestone by successfully developing the Durapontex N-Series using supercritical foaming technology, which requires consistent high temperature and pressure control. The result is an athlete’s dream—unmatched rebound, resilience, and guaranteed high energy return.

“The ultra-light weight and extremely high resilience in the Durapontex N-Series is something we haven’t seen in the industry before. We received great feedback when we athlete tested the N-Series at the Portland Track Festival this year, that it was amazingly soft and bouncy, as well as a new, favourite insole on the track.”

Fibre2Fashion News Desk (NB)