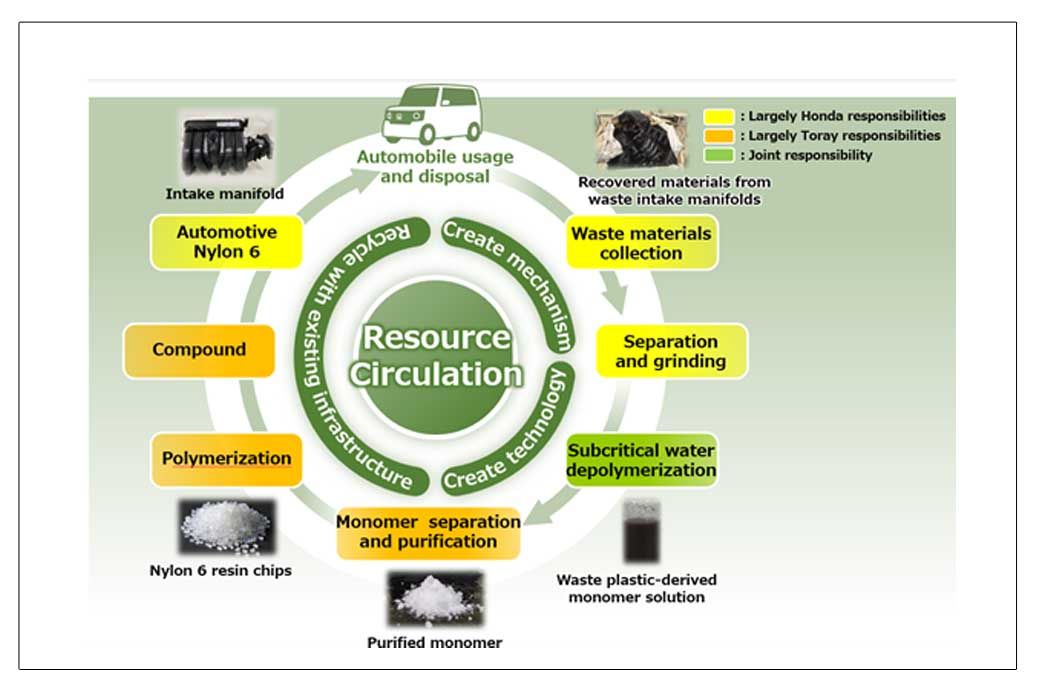

Toray Industries has announced that it has signed an agreement with Honda Motor, to jointly develop a chemical recycling technology for glass-fibre reinforced nylon 6 parts recovered from end-of-life vehicles. The two have begun verifying this technology, which entails depolymerising with subcritical water and regenerating the materials as caprolactam, a raw monomer.

The two companies focused on such subcritical water characteristics as its high permeability, dissolving power, and hydrolysis effect in resins in developing a technology that successfully depolymerises nylon 6 with that water. Subcritical water is water at high temperatures and pressures. It is free of catalysts, additives do not affect it, and it can depolymerise nylon 6 in several dozen minutes to create high yields of raw monomer. Separating, refining, and repolymerising that monomer makes it possible to regenerate nylon 6 that performs like a virgin material, the company said in a press release.

The ministry of environment adopted this technology for a fiscal 2023 project to establish a decarbonised circular economy system, including to validate recycling systems for plastics and other resources. Toray and Honda look to employ that project to set up a pilot facility with a processing capacity of 500 metric tons annually of raw resin, conducting validation testing with it.

The first step with this work is to recycle used automotive plastic parts into the same automotive materials. The two companies will develop depolymerisation and monomer separation and refining technologies by employing intake manifolds as raw materials for engine intake system parts. They seek to apply these technologies for recycling chemicals in automotive resin parts by around 2027.

Down the track, they look to broaden the scope of their chemical recycling technology to encompass apparel, films, and other non-automotive applications. They also envisage inviting other companies to take part in their effort and to set up a chemical recycling scheme for nylon 6 in Japan. This endeavour would help realisation a circular economy and cut greenhouse gas emissions.

One goal of the Toray Group Sustainability Vision for 2050 is to contribute to a world in resources that are sustainably managed. Toray will keep pursuing research and development to contribute to a sustainable, circular economy and thereby realise its corporate philosophy of contributing to social progress by delivering new value while attaining sustainable growth.

Fibre2Fashion News Desk (RR)